Are PVC Roof Sheets Resistant to Acid Rain Corrosion

Dec 02,2025

Dec 02,2025

Shenyu

Shenyu

For building material wholesalers, distributors, and contractors serving the commercial and industrial construction sectors, specifying roofing materials that can withstand harsh environmental conditions is critical. One of the most common yet damaging challenges, especially in industrial and certain geographic regions, is acid rain. The question arises: Are PVC roof sheets a viable, long-term solution for corrosion resistance? For professionals seeking reliable, durable, and low-maintenance roofing, the answer from leading UPVC roof sheets manufacturer SY/UNIKO Roof is a definitive yes. Our advanced PVC roof sheet and UPVC roof sheet products are engineered specifically to combat chemical corrosion, including that caused by acid rain, making them an intelligent choice for a wide range of demanding applications.

Understanding Acid Rain and Its Impact on Roofing

Acid rain forms when sulfur dioxide and nitrogen oxides are released into the atmosphere, often from industrial processes, and mix with water vapor. The resulting precipitation has a lower pH than normal rain, making it mildly to moderately acidic. Over time, this persistent acidity can corrode and degrade traditional roofing materials like certain metals, untreated wood, and even some low-quality plastics. This leads to:

- Loss of structural integrity

- Premature aging and failure

- Compromised waterproofing

- Unsightly stains and surface degradation

For a roofing material to be considered suitable for areas prone to acid rain, it must possess inherent chemical inertness and a formulated resistance to acidic compounds.

The Science Behind PVC's Corrosion Resistance

The primary component of PVC roof sheets is Polyvinyl Chloride (PVC), a synthetic plastic polymer known for its exceptional chemical stability. Unlike metals that undergo electrochemical reactions (rusting/corrosion) or organic materials that can break down, PVC is inherently resistant to a wide range of acids, alkalis, and salts. SY/UNIKO Roof takes this inherent advantage to the next level through sophisticated material science.

Our proprietary compound formula enhances base PVC with a suite of specialized additives:

Our proprietary compound formula enhances base PVC with a suite of specialized additives:

- High-Efficiency UV Stabilizers: Protect the polymer chain from solar degradation, preventing surface chalking, brittleness, and color fade, which can expose fresh material to chemical attack.

- Antioxidants: Further slow the aging process by preventing oxidative damage from heat and environmental exposure.

- Flame Retardants: Provide enhanced fire safety without compromising chemical resistance.

- Impact Modifiers: Maintain flexibility and strength across a range of temperatures.

This scientific formulation is not merely theoretical. Our plastic roof sheet products undergo rigorous testing. As verified by China's National Chemical Building Materials Testing Center, SY/UNIKO Roof's PVC sheets show no chemical reaction after 24-hour immersion in solutions of salt, alkali, and various acids at concentrations up to 60%. This empirical data proves their capability to withstand corrosive environments, including acid rain, far exceeding typical environmental exposure levels.

SY/UNIKO Roof's Comprehensive PVC Roofing Portfolio for Professionals

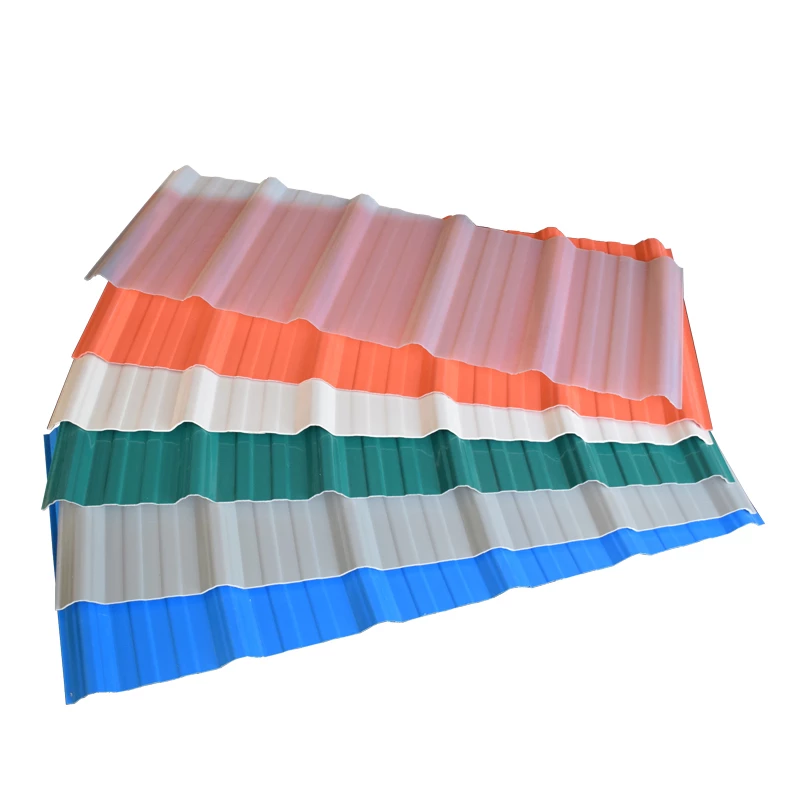

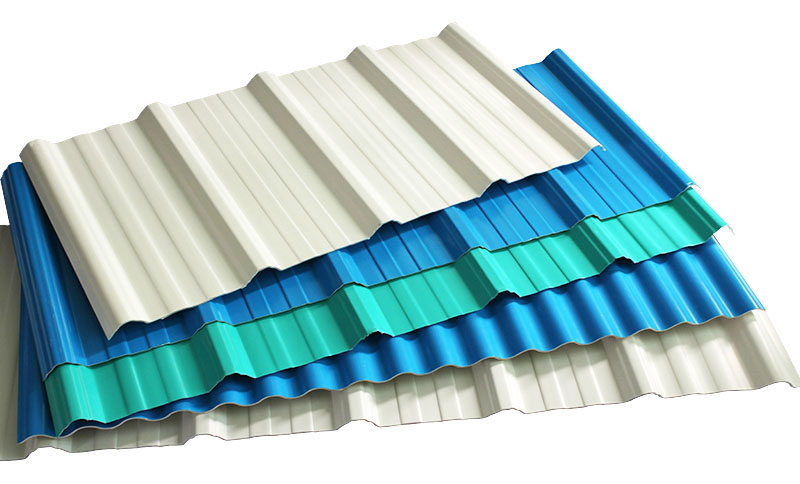

We offer a diversified range of PVC roof tiles and sheets, allowing distributors and contractors to provide the perfect solution for every project specification and client budget. Our core product lines include:

- PVC Corrosion-Resistant & Insulated Sheets: Integrate thermal insulation properties, reducing energy costs for climate-controlled facilities.

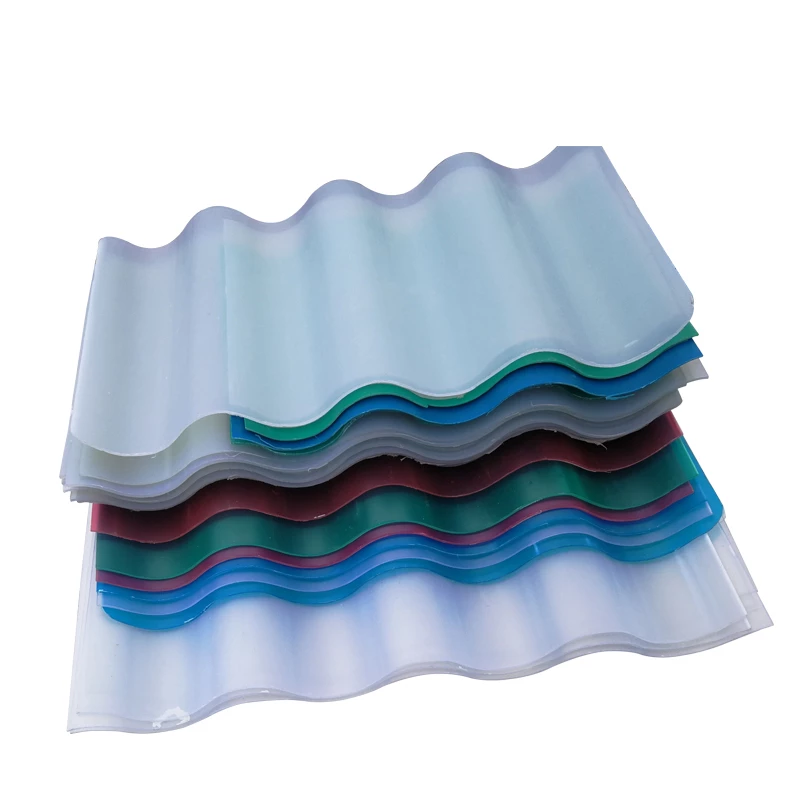

- PVC Semi-Transparent Sheets: Provide natural daylighting for interiors while maintaining full corrosion resistance, ideal for warehouses and market canopies.

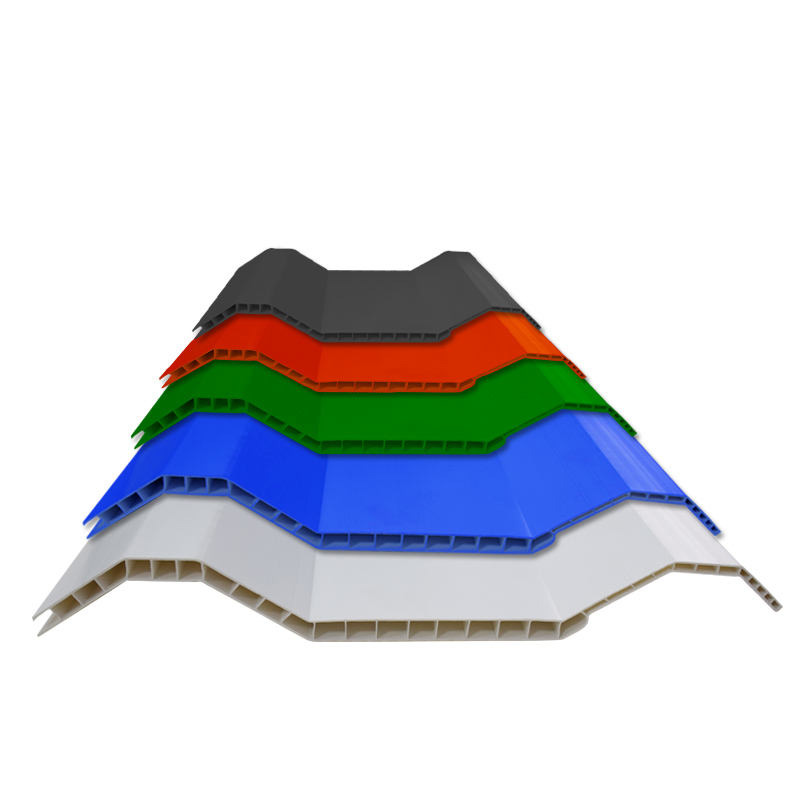

- PVC Hollow Twinwall Roof Sheets: Among various roofing materials, our uPVC hollow roof sheets have become a preferred choice for global residential and commercial projects, thanks to their exceptional durability and flexible design adaptability. The product is available in three standard widths—885mm, 960mm, and 930mm—and can be fully customized to meet specific needs. It offers UV resistance, all-weather protection, and long service life. Lightweight yet strong, it ensures easy installation and structural stability. We also support OEM/ODM cooperation, providing truly personalized roofing solutions.

- ASA-PVC Super Weather-Resistant Composite Roof Sheets: Our premium solution, featuring an ASA (Acrylic-Styrene-Acrylonitrile) cap layer. This provides ultimate protection against UV rays, extreme weather, and chemical corrosion, making it the top recommendation for the most severe environments, including heavy industrial zones and regions with frequent acid rain.

Key Advantages for Your Business and End Clients

Specifying SY/UNIKO Roof's UPVC roof sheet products provides tangible benefits that enhance your value proposition:

- Unmatched Durability & Long Lifespan: Resistance to acid rain, chemicals, rust, and rot translates to a dramatically extended service life with minimal maintenance. This reduces total cost of ownership and builds client trust.

- Lightweight & High Strength: Easier and safer to handle, transport, and install. Reduces structural load on buildings and cuts down on labor time and costs—a major selling point for contractors.

- Exceptional Weather Resistance: Beyond acid rain, our sheets resist hail impact, wind uplift, and thermal expansion/contraction, ensuring reliable performance year after year.

- Fire Safety: Inherent flame-retardant properties (typically meeting Class B standards) enhance building safety—a crucial factor in commercial specifications.

- Waterproof & Leak-Proof: One-piece, large-format sheets with sealed fixings ensure a completely watertight roof, eliminating leaks and water damage.

- Aesthetic Flexibility: Available in a variety of standard and custom colors that resist fading, allowing architects and builders to meet design requirements without sacrificing performance.

- Eco-Friendly & Sustainable: PVC is recyclable, and our long-lasting products reduce the frequency of roof replacement, minimizing construction waste.

Ideal Applications for Acid Rain-Resistant PVC Roofing

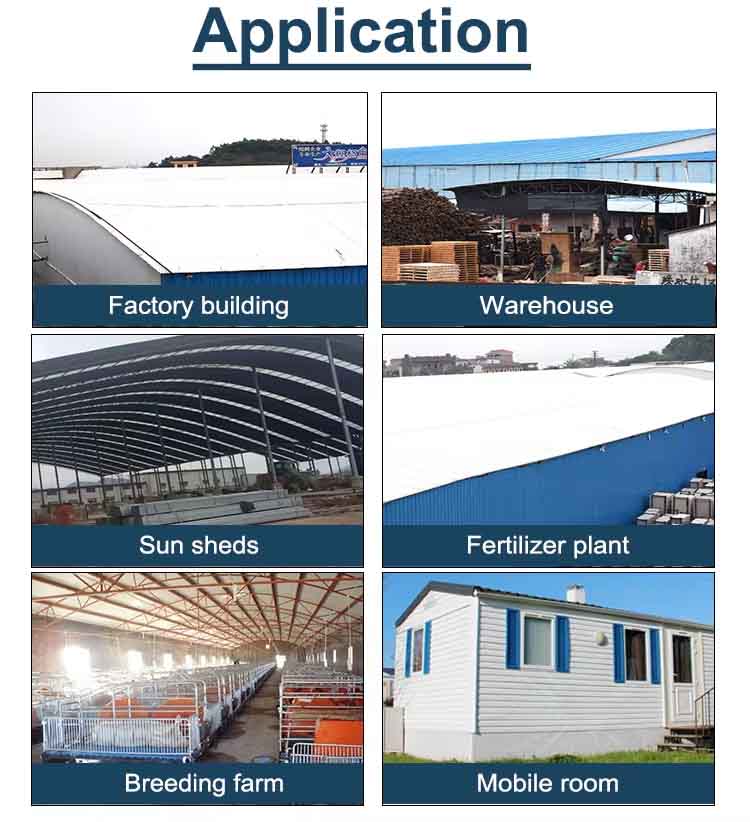

Our products are the specification of choice for numerous demanding applications:

- Chemical & Manufacturing Plants: Where airborne chemical emissions are common.

- Agricultural Buildings: Barns, stables, and processing facilities exposed to ammonia and organic acids.

- Coastal & Industrial Region Facilities: Prone to salt spray and acidic precipitation.

- Logistics Warehouses & Storage Units: Requiring large, low-maintenance, and durable roofs.

- Public Markets, Stadiums, and Transportation Hubs: Needing long-lasting, colorful, and safe roofing solutions.

Partner with SY/UNIKO Roof: Your Source for Superior Roofing Solutions

For wholesalers, distributors, and contractors, choosing a reliable manufacturer is as important as choosing the right product. SY/UNIKO Roof stands as your trusted partner, committed to:

- Consistent Quality: Rigorous in-house QC and third-party certifications guarantee every shipment meets our high standards.

- Bulk Supply Capability: We support large-scale projects and distributor inventories with reliable production capacity and on-time delivery.

- Technical & Sales Support: Our expert team provides specification guidance, CAD drawings, and installation advice to help you win and complete projects successfully.

- Competitive Pricing: Direct-from-factory pricing ensures you receive excellent value, maximizing your margin and competitiveness in the market.

Conclusion

In the face of environmental challenges like acid rain, not all roofing materials are created equal. PVC roof sheets from SY/UNIKO Roof, particularly our advanced UPVC roof tiles and composite sheets, are scientifically formulated and proven to offer superior, long-term corrosion resistance. By partnering with us, you equip your business with a premium product line that delivers the durability, performance, and value your commercial and industrial clients demand. Contact SY/UNIKO Roof today to request technical datasheets, samples, and a competitive wholesale quote, and elevate your roofing supply offerings.

Frequently Asked Questions (FAQs): Acid Rain Corrosion Resistance of PVC Roofing Sheets

Q1: Are your PVC roofing sheets truly resistant to acid rain? Is there specific test data to support this?

A1: Yes, our PVC roofing sheets offer excellent resistance to acid rain corrosion. This is not only due to the inherent properties of PVC material but also our unique formulation. We incorporate high-performance stabilizers and modifiers into the base material. Our products have been tested by the authoritative China National Chemical Building Materials Testing Center, with results showing that the panels showed no chemical corrosion reaction after being immersed in various acidic solutions with concentrations as high as 60%, as well as in salt and alkali solutions, for 24 hours. The concentration of acid rain in real-world environments is far lower than these test conditions, ensuring our panels provide long-term, reliable protection.

Q2: Which of your products should we choose for severe industrial pollution zones or coastal areas?

A2: For extremely harsh environments (such as heavy acid rain areas, near chemical plants, or coastal salt spray zones), we strongly recommend our ASA-PVC Super Weather-Resistant Composite Sheets. This is our top-tier product developed specifically for highly corrosive environments. It features a co-extruded surface layer of ASA (Acrylic-Styrene-Acrylonitrile) engineering plastic over a standard PVC core. The ASA layer provides unparalleled resistance to UV rays, chemical corrosion, and aging, ensuring long-lasting color vibrancy and protecting the substrate from direct erosion. It is the premier solution for such projects.

Q3: What is the difference between your PVC roofing sheets and traditional color steel/metal sheets in terms of corrosion resistance?

A3: This is one of the most significant advantages. Traditional metal sheets rely on surface coatings for rust prevention. Once this coating is damaged during transport, installation, or by acid rain corrosion, the base metal undergoes rapid electrochemical rusting, leading to perforation and leaks. In contrast, our UPVC roofing sheets are non-metallic, homogeneous materials with inherent chemical inertness throughout their structure—they do not rust. Their corrosion resistance is bulk-phase protection, not just surface protection, making it more thorough, durable, and resulting in a significantly longer service life than ordinary metal sheets.

Q4: Besides corrosion resistance, what other advantages do your PVC sheets offer that would appeal to my end clients?

A4: In addition to exceptional resistance to acid rain and chemical corrosion, our products deliver comprehensive value to your end clients:

A1: Yes, our PVC roofing sheets offer excellent resistance to acid rain corrosion. This is not only due to the inherent properties of PVC material but also our unique formulation. We incorporate high-performance stabilizers and modifiers into the base material. Our products have been tested by the authoritative China National Chemical Building Materials Testing Center, with results showing that the panels showed no chemical corrosion reaction after being immersed in various acidic solutions with concentrations as high as 60%, as well as in salt and alkali solutions, for 24 hours. The concentration of acid rain in real-world environments is far lower than these test conditions, ensuring our panels provide long-term, reliable protection.

Q2: Which of your products should we choose for severe industrial pollution zones or coastal areas?

A2: For extremely harsh environments (such as heavy acid rain areas, near chemical plants, or coastal salt spray zones), we strongly recommend our ASA-PVC Super Weather-Resistant Composite Sheets. This is our top-tier product developed specifically for highly corrosive environments. It features a co-extruded surface layer of ASA (Acrylic-Styrene-Acrylonitrile) engineering plastic over a standard PVC core. The ASA layer provides unparalleled resistance to UV rays, chemical corrosion, and aging, ensuring long-lasting color vibrancy and protecting the substrate from direct erosion. It is the premier solution for such projects.

Q3: What is the difference between your PVC roofing sheets and traditional color steel/metal sheets in terms of corrosion resistance?

A3: This is one of the most significant advantages. Traditional metal sheets rely on surface coatings for rust prevention. Once this coating is damaged during transport, installation, or by acid rain corrosion, the base metal undergoes rapid electrochemical rusting, leading to perforation and leaks. In contrast, our UPVC roofing sheets are non-metallic, homogeneous materials with inherent chemical inertness throughout their structure—they do not rust. Their corrosion resistance is bulk-phase protection, not just surface protection, making it more thorough, durable, and resulting in a significantly longer service life than ordinary metal sheets.

Q4: Besides corrosion resistance, what other advantages do your PVC sheets offer that would appeal to my end clients?

A4: In addition to exceptional resistance to acid rain and chemical corrosion, our products deliver comprehensive value to your end clients:

- Lightweight & High Strength: Only one-third the weight of color steel sheets, significantly reducing structural load on buildings. Easy and safe to install, saving labor and hoisting costs.

- Fire Retardant & Insulating: Achieves a flame-retardant Class B1 rating and is non-conductive, enhancing building safety.

- Thermal Insulation & Energy Saving: Low thermal conductivity. Combined with our PVC Anti-Corrosion & Insulated Sheets, they effectively reduce indoor temperatures and save on air conditioning costs.

- Sealed & Leak-Proof: Features large-span corrugation design with tight overlaps, paired with professional waterproof fittings for integrated water resistance.

Q5: Will the color fade? How long can it last under acid rain and UV exposure?

A5: Our products offer outstanding color stability, thanks to the high-efficiency UV inhibitors and premium colorants in our formulation. For standard PVC sheets, we guarantee no significant fading for 5-10 years under normal climatic conditions. For our ASA-PVC Super Weather-Resistant Composite Sheets, the ASA surface layer itself is an excellent color-preserving material, offering superior resistance to fading and gloss retention. Color durability can exceed 15 years, maintaining the building's aesthetic appeal long-term.

Q6: What is the Minimum Order Quantity (MOQ)? Do you support custom colors and sizes?

A6: As a manufacturer targeting wholesalers and contractors, we offer flexible cooperation terms. Our container MOQ for standard products is highly competitive. We fully support customization, including specific lengths, widths, thicknesses, profiles, and any color from RAL or Pantone color charts based on your project needs. Specific MOQ and pricing for custom orders may vary slightly. Our sales team will provide you with the most economical solution.

Q7: How are they installed? Do they require special tools or systems?

A7: Installation is very straightforward, similar to installing traditional corrugated metal sheets, using common tools like electric drills and self-tapping screws. We provide a complete dedicated waterproof fastening system (including self-drilling screws, sealing washers, and decorative caps) to ensure every fixing point is sealed and waterproof. We can provide detailed installation manuals with shipments and offer remote or on-site technical installation support for large projects.

Q8: What market support can you provide to distributors?

A8: SY/UNIKO Roof is committed to building mutually beneficial partnerships with distributors. Our support includes:

A5: Our products offer outstanding color stability, thanks to the high-efficiency UV inhibitors and premium colorants in our formulation. For standard PVC sheets, we guarantee no significant fading for 5-10 years under normal climatic conditions. For our ASA-PVC Super Weather-Resistant Composite Sheets, the ASA surface layer itself is an excellent color-preserving material, offering superior resistance to fading and gloss retention. Color durability can exceed 15 years, maintaining the building's aesthetic appeal long-term.

Q6: What is the Minimum Order Quantity (MOQ)? Do you support custom colors and sizes?

A6: As a manufacturer targeting wholesalers and contractors, we offer flexible cooperation terms. Our container MOQ for standard products is highly competitive. We fully support customization, including specific lengths, widths, thicknesses, profiles, and any color from RAL or Pantone color charts based on your project needs. Specific MOQ and pricing for custom orders may vary slightly. Our sales team will provide you with the most economical solution.

Q7: How are they installed? Do they require special tools or systems?

A7: Installation is very straightforward, similar to installing traditional corrugated metal sheets, using common tools like electric drills and self-tapping screws. We provide a complete dedicated waterproof fastening system (including self-drilling screws, sealing washers, and decorative caps) to ensure every fixing point is sealed and waterproof. We can provide detailed installation manuals with shipments and offer remote or on-site technical installation support for large projects.

Q8: What market support can you provide to distributors?

A8: SY/UNIKO Roof is committed to building mutually beneficial partnerships with distributors. Our support includes:

- Technical Documentation Pack: High-resolution product images, technical data sheets, test reports, CAD drawings, and installation videos.

- Sample Support: Free samples for major potential projects.

- Co-marketing: Provision of product brochures, exhibition materials, and featuring quality distributors on our official website and B2B platforms.

- Price Protection & Inventory Advice: Competitive pricing and reasonable inventory planning advice for long-term partners.

- After-sales Service: A responsive after-sales channel to address any quality or technical inquiries.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

SY ROOF - Leading Chinese Manufacturer of UPVC Roofing Sheets in China

SY ROOF - Leading Chinese Manufacturer of UPVC Roofing Sheets in China