How to Evaluate the High-Temperature Resistance of ASA Synthetic Resin Roof Sheets

Sep 06,2025

Sep 06,2025

Shenyu

Shenyu

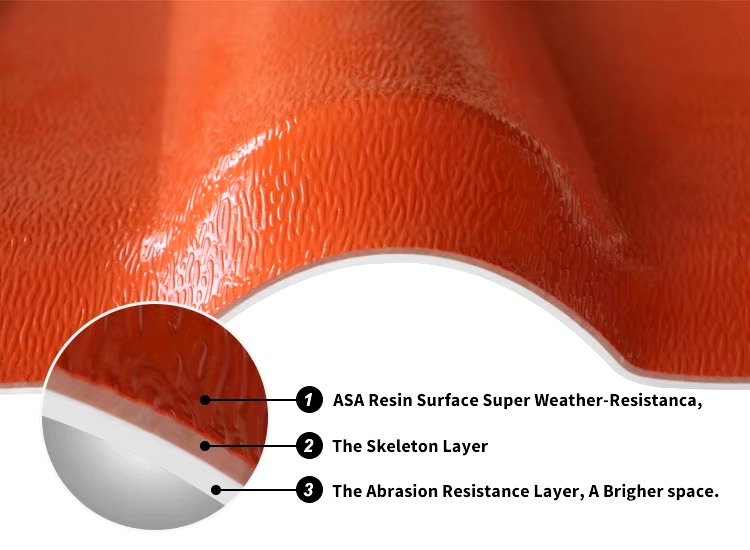

In the field of roofing materials, ASA synthetic resin roof sheets have become a preferred choice for modern construction due to their lightweight yet high strength, waterproofing, thermal insulation, corrosion resistance, and self-cleaning properties. However, high-temperature resistance is a critical indicator of roofing materials under extreme conditions such as high temperatures and fires. How can this property be scientifically evaluated? This article analyzes the high-temperature performance of ASA synthetic resin roof sheets from four key dimensions—mechanical properties, toxicity, combustion behavior, and thermal insulation—and introduces how SY/Uniko ROOF utilizes advanced technology and material engineering to provide users with safe and reliable roofing solutions.

1. Mechanical Properties: Dimensional Stability Under High Temperatures

Dimensional stability is crucial for roofing materials in high-temperature environments. ASA synthetic resin roof sheets are manufactured using three-layer co-extrusion technology, with a base material made of ultra-high weather-resistant ASA engineering resin. They exhibit an extremely low thermal expansion coefficient (4.9×10⁻⁵ mm/mm/℃). This means that even under significant temperature changes, the tiles can absorb deformation through their bidirectional stretching properties, preventing warping, cracking, or detachment caused by thermal stress, thereby maintaining long-term geometric stability.

SY/Uniko ROOF’s ASA UPVC roof tiles further optimize the material formulation and structural design, allowing them to maintain excellent mechanical performance and dimensional integrity within a temperature range of -40°C to 120°C, making them suitable for various climatic regions.

SY/Uniko ROOF’s ASA UPVC roof tiles further optimize the material formulation and structural design, allowing them to maintain excellent mechanical performance and dimensional integrity within a temperature range of -40°C to 120°C, making them suitable for various climatic regions.

2. Toxicity and Fire Safety: Suppressing Toxic Smoke Generation

In fire scenarios, the toxicity of material combustion directly impacts human safety. Unlike traditional building materials, synthetic resin roof tiles do not produce molten droplets when burned at high temperatures, effectively avoiding secondary ignition risks. More importantly, they generate lower smoke density and release significantly fewer toxic gases compared to many conventional materials.

SY/Uniko ROOF’s ASA resin roof tiles use environmentally friendly high-molecular polymers as the main raw material and incorporate efficient flame retardants, significantly reducing smoke density and toxic gas emissions in fires, buying valuable time for evacuation and firefighting.

SY/Uniko ROOF’s ASA resin roof tiles use environmentally friendly high-molecular polymers as the main raw material and incorporate efficient flame retardants, significantly reducing smoke density and toxic gas emissions in fires, buying valuable time for evacuation and firefighting.

3. Combustion Performance: Fire Resistance Class B1 Assurance

According to the "Code for Fire Prevention in Building Design," materials' combustion performance is classified into multiple levels, with Class B1 (flame-retardant) being a higher standard for roofing materials. ASA synthetic resin roof tiles have an oxygen index below 20. Their raw material—a ternary copolymer of acrylonitrile, styrene, and acrylic rubber—inherently exhibits good flame-retardant properties, further enhanced by flame retardants added during production.

Thus, SY/Uniko ROOF’s ASA synthetic resin roof sheets successfully meet the Class B1 fire certification, characterized by "self-extinguishing upon flame removal." In open flames, these tiles neither fuel the fire nor produce molten droplets, effectively delaying the spread of flames and improving the overall fire resistance of buildings.

Thus, SY/Uniko ROOF’s ASA synthetic resin roof sheets successfully meet the Class B1 fire certification, characterized by "self-extinguishing upon flame removal." In open flames, these tiles neither fuel the fire nor produce molten droplets, effectively delaying the spread of flames and improving the overall fire resistance of buildings.

4. Thermal Insulation: Efficient Barrier Against Heat Transfer

The thermal insulation performance of roofing materials directly affects building energy consumption and indoor comfort. The thermal conductivity of ASA synthetic resin roof tiles is only 0.325 W/m·K, significantly lower than that of common roofing materials:

- Approximately 1/310 that of clay tiles

- Equivalent to 1/5 that of cement tiles

- Only 1/200 that of 0.5mm-thick color steel sheets

A low thermal conductivity means that ASA resin roof tiles can effectively block solar radiation heat in summer, reducing indoor temperatures, while in fires, they can delay the transfer of heat to the interior structure, providing more time for evacuation and property protection.

SY/Uniko ROOF’s products further enhance thermal insulation efficiency through multi-layer composite structures and hollow designs, making them particularly suitable for high-temperature regions and buildings with high fire safety requirements, such as industrial and civil constructions.

SY/Uniko ROOF’s products further enhance thermal insulation efficiency through multi-layer composite structures and hollow designs, making them particularly suitable for high-temperature regions and buildings with high fire safety requirements, such as industrial and civil constructions.

5. SY/Uniko ROOF: Redefining High-Temperature-Resistant Roofing Materials with Technology

As a leading manufacturer of ASA synthetic resin roof sheets, SY/Uniko ROOF is committed to enhancing the high-temperature adaptability of its products through technological innovation:

- Uses pure virgin ASA engineering resin, avoiding recycled materials to ensure consistency;

- Employs co-extrusion molding technology to achieve permanent bonding between the ASA protective layer and PVC substrate;

- Incorporates efficient halogen-free flame retardants to achieve Class B1 fire resistance and low smoke toxicity;

- Fully complies with SGS high-temperature deformation, oxygen index, and smoke toxicity tests.

Conclusion: High-Temperature Resistance Is a Systematic Engineering Task

Evaluating the high-temperature resistance of ASA synthetic resin roofing sheets requires a comprehensive consideration of multiple factors, including thermal stability, fire rating, smoke toxicity, and thermal insulation performance. With robust material research and precise manufacturing processes, SY/Uniko ROOF provides users with a comprehensive high-temperature-adaptive roofing system solution, contributing to the construction of safer, more energy-efficient, and durable buildings.

Tip: When purchasing, look for products with Class B1 fire test reports and clear ingredient descriptions. Avoid inferior tiles with added calcium powder to ensure long-term roofing safety.

Tip: When purchasing, look for products with Class B1 fire test reports and clear ingredient descriptions. Avoid inferior tiles with added calcium powder to ensure long-term roofing safety.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

How to Choose the Right Corrugated Polycarbonate Roof Sheet for Your Project

How to Choose the Right Corrugated Polycarbonate Roof Sheet for Your Project