The Truth About ASA PVC Roof Sheets: A Comprehensive Guide for Building Professionals

Aug 12,2025

Aug 12,2025

Shenyu

Shenyu

For over a decade, a critical question has haunted the construction industry: Are synthetic resin roof tiles a viable long-term solution or just a temporary fix? Online forums are filled with alarming headlines: "Why Synthetic Resin Roof Tiles Are Failing," "The Rise and Fall of Resin Roofing," and "How Cheap Roof Tiles Fail Within 3 Years." Yet, alongside these warnings, there exists compelling evidence of installations that have performed flawlessly for over 15 years. The crucial difference lies not in the material category itself, but in quality, composition, and manufacturing integrity. This guide cuts through the noise, explaining why ASA PVC roof sheets from reputable UPVC roofing sheets manufacturers like SY/UNIKO Roof represent a superior, durable choice for modern construction projects.

Understanding the Market Divide: Quality vs. Compromise

The controversy surrounding synthetic roofing stems from a fundamental market split. Early adopters who experienced failures typically purchased products made from recycled materials at prices as low as $3-4 per square meter. These inferior ASA roofing sheet alternatives, essentially disposable solutions for temporary structures, degraded rapidly—fading to a dull gray, cracking under thermal stress, and developing leaks within five years.

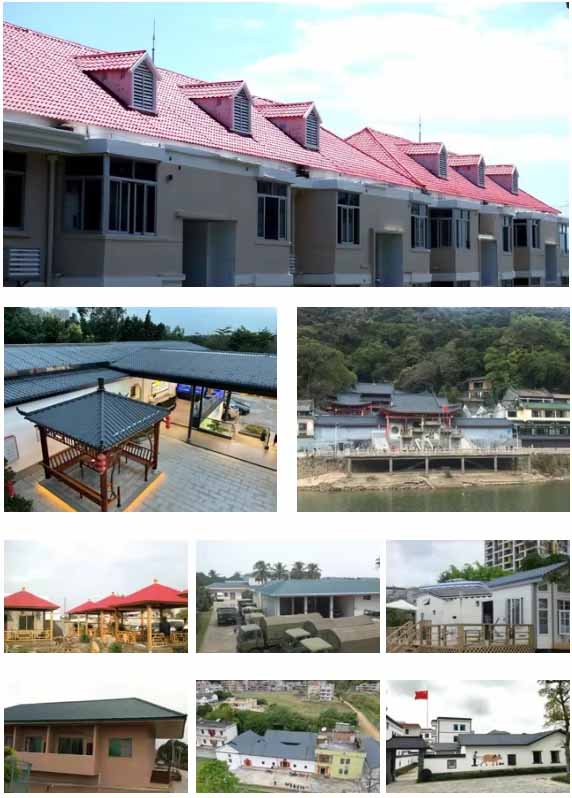

Conversely, installations using premium-grade materials from certified manufacturers tell a different story. Consider documented cases from Henan and Zhejiang provinces, where roofs installed with high-quality synthetic tiles over a decade ago remain in excellent condition. These tiles retain their vibrant color (with color shift ΔE < 5), demonstrate remarkable韧性 (surviving hailstorms unscathed), and maintain completely watertight seals. The confidence behind such performance is often backed by substantial warranties—some up to 35 years—and even unique guarantees against hail damage, supported by comprehensive insurance from providers like PICC. This stark contrast highlights a critical truth: the problem isn't synthetic roofing as a concept; it's the proliferation of substandard products that has eroded market trust.

Conversely, installations using premium-grade materials from certified manufacturers tell a different story. Consider documented cases from Henan and Zhejiang provinces, where roofs installed with high-quality synthetic tiles over a decade ago remain in excellent condition. These tiles retain their vibrant color (with color shift ΔE < 5), demonstrate remarkable韧性 (surviving hailstorms unscathed), and maintain completely watertight seals. The confidence behind such performance is often backed by substantial warranties—some up to 35 years—and even unique guarantees against hail damage, supported by comprehensive insurance from providers like PICC. This stark contrast highlights a critical truth: the problem isn't synthetic roofing as a concept; it's the proliferation of substandard products that has eroded market trust.

The Unmatched Advantages of Premium ASA PVC Roofing Systems

When manufactured to the highest standards, ASA UPVC roofing sheet systems offer a combination of benefits that traditional materials struggle to match, making them an intelligent choice for wholesalers and contractors to recommend.

- Minimal Structural Load: At only 4-6 kg per square meter (approximately 1/4 the weight of color steel sheets and 1/10 of ceramic tiles), these tiles exert negligible pressure on supporting structures. This makes them ideal for retrofitting old buildings, heritage restoration projects, and new lightweight constructions without requiring significant reinforcement.

- Environmental Sustainability: The production of premium ASA PVC tiles has a significantly lower environmental footprint compared to alternatives. They generate only 50% of the carbon emissions of ceramic tile production and 30% lower PM2.5 emissions than stone-coated metal. With high recyclability rates (up to 80%) and low VOC emissions, they are increasingly specified in government-backed green building initiatives.

- Enhanced Safety: Quality tiles achieve a B1 fire-resistance rating, meaning they are difficult to ignite and will self-extinguish when the flame source is removed, meeting stringent safety requirements for residential and commercial buildings.

2. Exceptional Weather and Chemical Resistance

Premium ASA PVC roof sheet products are engineered to withstand harsh environments. Rigorous testing involves immersing samples in concentrated acid, alkali, and salt solutions for 72 hours—simulating conditions far worse than typical acid rain, coastal salt spray, or industrial pollution. High-quality sheets show no blistering, cracking, peeling, or significant discoloration, proving their suitability for chemical plants, coastal properties, and areas with severe industrial emissions.

3. Installation Efficiency and Cost-Effectiveness

The modular design of ASA Synthetic Resin Roof Tiles allows for rapid, "Lego-like" installation. Panels are custom-cut to length off-site, arriving ready for immediate assembly. A skilled crew can often complete an installation in a single day, drastically reducing labor costs and eliminating the delays and coordination errors common in multi-trade, multi-stage roofing projects.

4. Design Versatility and Aesthetic Flexibility

Modern manufacturing allows for incredible design freedom:

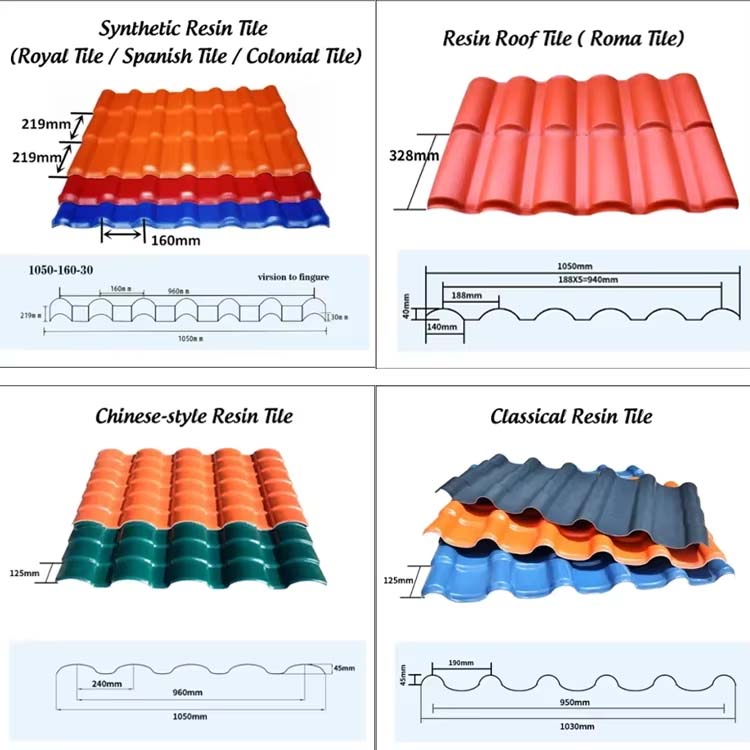

- Profiles: Options include standard synthetic tiles, classical profiles, small-curve "Qing" tiles, and Roman styles, suitable for everything from minimalist modern designs to traditional Chinese or European architecture.

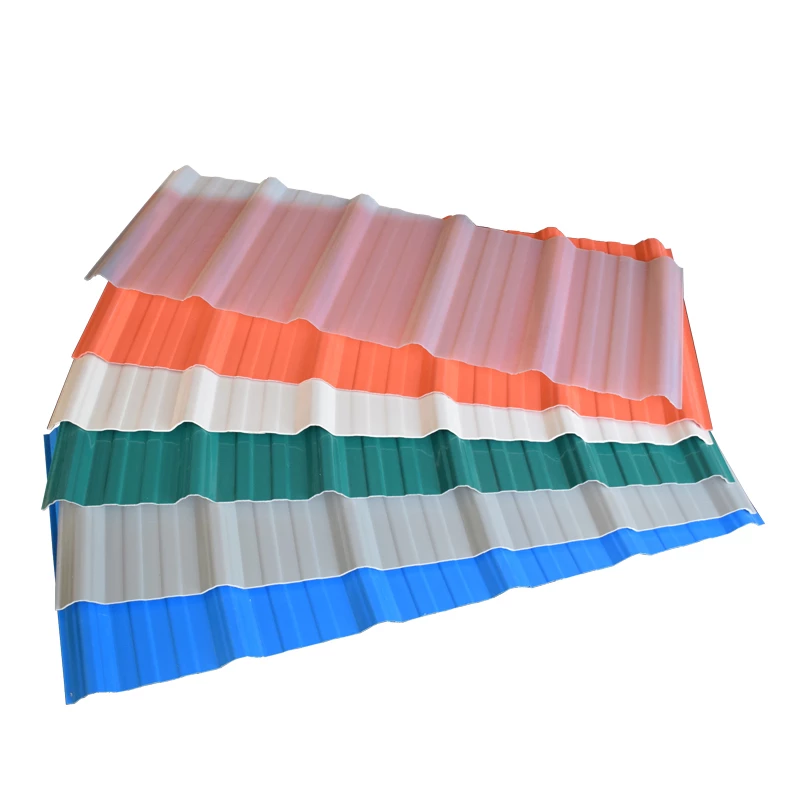

- Colors & Finishes: The use of an ASA cap-stock layer enables a vast color palette—from standard grays, blues, and reds to custom shades like Tiffany Blue or Burgundy. Textures (fine or coarse grain) can be customized via extrusion molds, affecting hydrophobics, light reflection, and the tile's three-dimensional character.

Navigating Quality and Pricing: A Guide for Professionals

For distributors and contractors, understanding the market's price and quality spectrum is key to making informed recommendations and protecting your reputation.

- Pricing Reference Table (2025 Market)

Brand Tier | Recommended Thickness (Residential) | Material Price (per m²) | Installed Price Reference (per m²) |

Standard Quality (e.g., SY/UNIKO Standard Line) | 2.5 mm (Standard) | $4 - $6 | $11 - $16 |

Premium Quality (e.g., SY/UNIKO Premium Line) | 3.0 mm (Optimal) | $6 - $9 | $16 - $20 |

Budget/Unbranded | Often < 2.0 mm | $1.5 - $3 | — (High risk of failure) |

Crucial Note on Pricing: In Southern China, pricing is typically per square meter. In other regions, it may be quoted per linear meter. For a standard 880mm-effective-width sheet, the per-square-meter price = linear meter price ÷ 0.88. Always confirm the unit of measurement.

The Pillars of True Quality: Beyond the Surface

The disparity in performance and price is rooted in material science and manufacturing ethics.

- Virgin Materials are Non-Negotiable: Reputable manufacturers like SY/UNIKO Roof use only 100% virgin PVC and ASA resins, never incorporating recycled content. This is the foundational barrier against premature brittleness and cracking.

- The "Premium Virgin Material" Difference: Beyond using virgin material, quality depends on the resin's purity and origin. Top-tier manufacturers source high-purity, often imported, resins. The molecular stability and consistency of these premium polymers directly translate to superior long-term weatherability and impact resistance.

- Specialized (and Costly) Additives: Performance is enhanced with expensive modifiers—high-efficiency UV inhibitors, impact modifiers, and heat stabilizers. These are often sourced from global chemical leaders and accompanied by certifications like RoHS, ensuring no harmful heavy metals are present.

- Precision Engineering and Process Control: Quality is locked in through advanced co-extrusion technology. This process precisely fuses the durable ASA top layer with the structural PVC core under strict heat and pressure controls. Adherence to ISO 9001 quality management systems ensures every batch meets the same high standard, delivering the promised "high quality at a competitive price."

Conclusion: Making an Informed Choice for Your Clients

The narrative is clear: ASA PVC and synthetic resin roofing are not inherently flawed; poor-quality iterations are. As industry veterans and contributors to national standards have emphasized, this material category—when produced correctly—offers a lightweight, safe, durable, and environmentally sound roofing solution that has been proven in global markets for over two decades.

The key for building material professionals is partnering with credible manufacturers. Choose partners like SY/UNIKO Roof, who are committed to transparency, use certified virgin materials, employ advanced manufacturing processes, and stand behind their products with meaningful warranties. By doing so, you move beyond the market's confusion, offering your clients a reliable, high-performance roofing solution that will protect their investments for decades to come.

The key for building material professionals is partnering with credible manufacturers. Choose partners like SY/UNIKO Roof, who are committed to transparency, use certified virgin materials, employ advanced manufacturing processes, and stand behind their products with meaningful warranties. By doing so, you move beyond the market's confusion, offering your clients a reliable, high-performance roofing solution that will protect their investments for decades to come.

FAQs for Distributors & Contractors

Q1: How can I verify if an ASA PVC roof sheet supplier uses 100% virgin materials?

A1: Reputable manufacturers are transparent. Request a Material Data Sheet (MDS) or Certificate of Analysis for the raw resins. Look for suppliers who openly state a "no-recycled-content" policy. SY/UNIKO Roof, for instance, provides documentation tracing our primary resins to major global chemical producers. Be wary of suppliers who are vague or refuse to provide compositional details.

Q2: What is the real lifespan we should quote to clients for a premium ASA PVC roof?

A2: For premium products like those from SY/UNIKO Roof's top lines, you can confidently quote a design life of 25-30 years under normal conditions. This is supported by accelerated weathering tests (like QUV testing for over 10,000 hours) and real-world track records. We offer a 10-15 year product warranty against manufacturing defects and significant fading (ΔE < 5), which serves as our formal performance guarantee.

Q3: Are these sheets suitable for extreme climates, like heavy snow loads or coastal hurricanes?

A3: Yes, but specification is key. For heavy snow areas, specify a thicker gauge (3.0mm or above) and ensure proper purlin spacing per our engineering tables. For coastal, high-wind zones, our sheets have excellent corrosion resistance, but the installation system is critical. We provide hurricane-grade clips and detailed wind-uplift resistant installation protocols that must be followed to ensure system performance.

Q4: How do we handle installation, and is special training required?

A4: Installation is straightforward for experienced metal roof installers. The primary differences are:

A1: Reputable manufacturers are transparent. Request a Material Data Sheet (MDS) or Certificate of Analysis for the raw resins. Look for suppliers who openly state a "no-recycled-content" policy. SY/UNIKO Roof, for instance, provides documentation tracing our primary resins to major global chemical producers. Be wary of suppliers who are vague or refuse to provide compositional details.

Q2: What is the real lifespan we should quote to clients for a premium ASA PVC roof?

A2: For premium products like those from SY/UNIKO Roof's top lines, you can confidently quote a design life of 25-30 years under normal conditions. This is supported by accelerated weathering tests (like QUV testing for over 10,000 hours) and real-world track records. We offer a 10-15 year product warranty against manufacturing defects and significant fading (ΔE < 5), which serves as our formal performance guarantee.

Q3: Are these sheets suitable for extreme climates, like heavy snow loads or coastal hurricanes?

A3: Yes, but specification is key. For heavy snow areas, specify a thicker gauge (3.0mm or above) and ensure proper purlin spacing per our engineering tables. For coastal, high-wind zones, our sheets have excellent corrosion resistance, but the installation system is critical. We provide hurricane-grade clips and detailed wind-uplift resistant installation protocols that must be followed to ensure system performance.

Q4: How do we handle installation, and is special training required?

A4: Installation is straightforward for experienced metal roof installers. The primary differences are:

- Use stainless steel or aluminum fasteners with EPDM washers (never standard steel screws).

- Follow the specific thermal expansion gap guidelines we provide.

- Use our matching ridge, eave, and flashing systems for a watertight seal.

We provide comprehensive installation manuals, video guides, and offer on-site or virtual training for our major distributor partners.

Q5: What is your MOQ, and can you support private labeling for distributors?

A5: Our standard MOQ is one 20-foot container. We strongly support our distribution partners and offer private labeling (OEM) services for partners with consistent volume commitments. We can customize packaging, include your branding on protective films, and work with you to develop co-branded marketing materials. Contact our sales team to discuss a partnership proposal tailored to your market goals.

A5: Our standard MOQ is one 20-foot container. We strongly support our distribution partners and offer private labeling (OEM) services for partners with consistent volume commitments. We can customize packaging, include your branding on protective films, and work with you to develop co-branded marketing materials. Contact our sales team to discuss a partnership proposal tailored to your market goals.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

Synthetic Spanish Roof Tiles Cost: A Key Consideration for Distributors, Contractors & Traders

Synthetic Spanish Roof Tiles Cost: A Key Consideration for Distributors, Contractors & Traders