What is Anti-Corrosion UPVC Roofing Sheet? Why Has It Become the Preferred Choice for Factories and Markets?

Jul 24,2025

Jul 24,2025

Shenyu

Shenyu

In the rapidly evolving field of industrial construction, roofing materials face new challenges. From chemical exposure in factories to high humidity in markets and intense UV radiation in outdoor corridors, traditional roofing materials such as metal sheets or asbestos tiles are showing signs of aging. Corrosion, thermal expansion, noise, and high maintenance requirements are common complaints among contractors and building owners.

Anti-corrosion UPVC roofing sheet represents a new generation of plastic roofing sheets specifically designed to meet the needs of modern factories, warehouses, and commercial buildings. These roofing sheets utilize multi-layer extrusion technology and are reinforced with UV-resistant and acid-resistant components, making them lightweight, durable, and highly effective in harsh environments.

As the construction industry shifts toward low-maintenance, efficient, and cost-effective materials, anti-corrosion PVC roofing has gained increasing popularity in Southeast Asia and Africa. But what exactly is it? Why has it become the preferred choice for so many large-scale projects?

This article provides a clear, scientifically grounded explanation of anti-corrosion UPVC roofing sheet—its composition, working principles, applications, and comparison with traditional roofing systems.

Anti-corrosion UPVC roofing sheet represents a new generation of plastic roofing sheets specifically designed to meet the needs of modern factories, warehouses, and commercial buildings. These roofing sheets utilize multi-layer extrusion technology and are reinforced with UV-resistant and acid-resistant components, making them lightweight, durable, and highly effective in harsh environments.

As the construction industry shifts toward low-maintenance, efficient, and cost-effective materials, anti-corrosion PVC roofing has gained increasing popularity in Southeast Asia and Africa. But what exactly is it? Why has it become the preferred choice for so many large-scale projects?

This article provides a clear, scientifically grounded explanation of anti-corrosion UPVC roofing sheet—its composition, working principles, applications, and comparison with traditional roofing systems.

1. What is Anti-Corrosion UPVC Roofing Sheet?

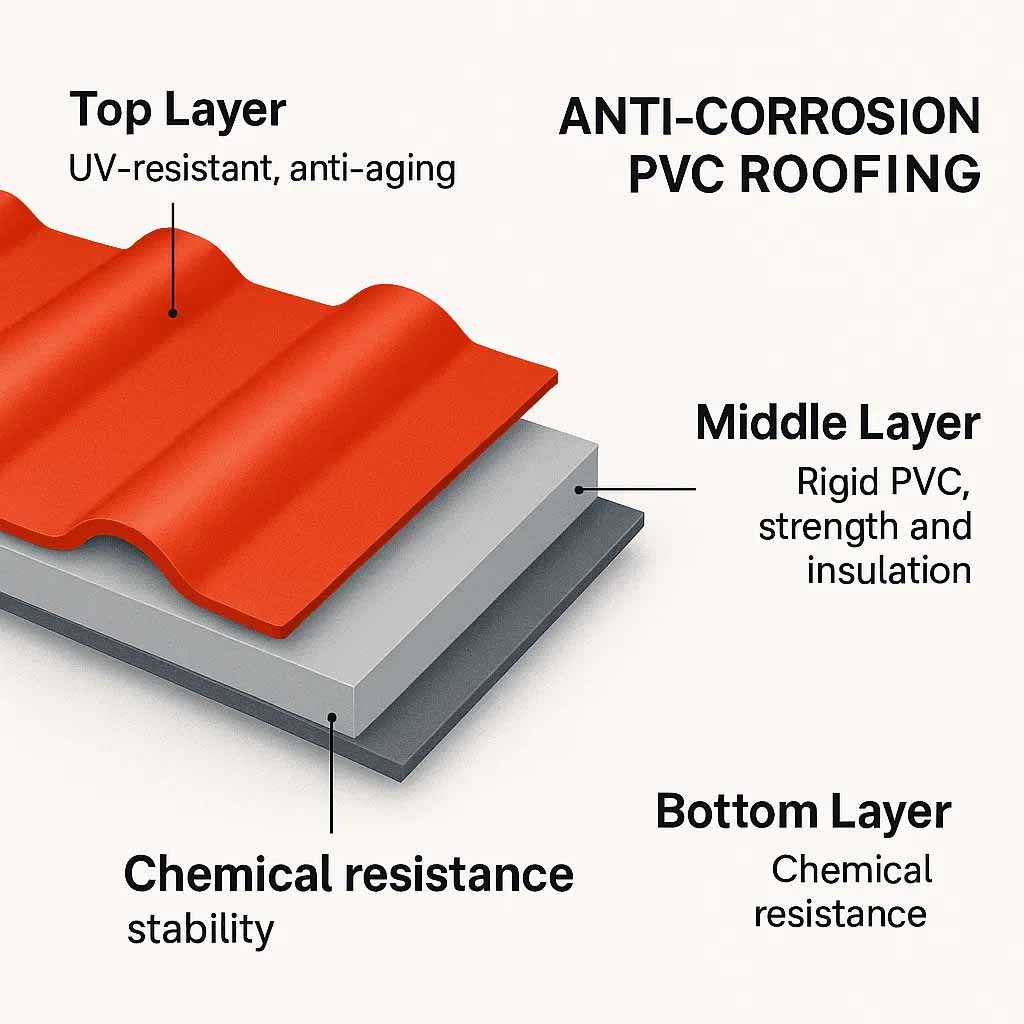

Anti-corrosion PVC roofing is a plastic-based roofing sheet designed using multi-layer co-extrusion technology. Unlike traditional single-layer plastic or metal roofing, it typically consists of two to three functional layers:

Top Layer: Made from UV-resistant and anti-aging compounds (sometimes including ASA resin) to prevent solar degradation and fading.

Middle Layer: Reinforced with rigid PVC or calcium-zinc stabilizers to enhance structural strength and thermal insulation.

Bottom Layer: Engineered for chemical resistance and stability in humid or corrosive environments.

This structure enables the sheets to withstand acid rain, salt spray, ammonia, industrial fumes, and prolonged exposure to tropical humidity. Additionally, they are lightweight, typically 60% to 70% lighter than metal sheets, making installation easier and safer for factory and warehouse roofs.

In the global B2B market, this material may be referred to as multi-layer PVC roofing sheets, corrosion-resistant plastic roofing, or simply industrial PVC roofing sheets. The term "UPVC" is commonly used in Asian manufacturing industries, though it may not always be recognized by Western buyers.

Top Layer: Made from UV-resistant and anti-aging compounds (sometimes including ASA resin) to prevent solar degradation and fading.

Middle Layer: Reinforced with rigid PVC or calcium-zinc stabilizers to enhance structural strength and thermal insulation.

Bottom Layer: Engineered for chemical resistance and stability in humid or corrosive environments.

This structure enables the sheets to withstand acid rain, salt spray, ammonia, industrial fumes, and prolonged exposure to tropical humidity. Additionally, they are lightweight, typically 60% to 70% lighter than metal sheets, making installation easier and safer for factory and warehouse roofs.

In the global B2B market, this material may be referred to as multi-layer PVC roofing sheets, corrosion-resistant plastic roofing, or simply industrial PVC roofing sheets. The term "UPVC" is commonly used in Asian manufacturing industries, though it may not always be recognized by Western buyers.

2. The Science Behind Its Anti-Corrosion Properties

What makes anti-corrosion PVC roofing sheet so effective in harsh environments such as coastal areas, chemical plants, and livestock farms? The secret lies in its multi-layer polymer structure and the chemical additives that protect the material at the molecular level.

Calcium-Zinc Stabilizers: Added during production to replace toxic lead-based stabilizers, enhancing resistance to acid rain, ammonia, and high humidity.

UV-Resistant Outer Layer: Prevents surface degradation, which often leads to micro-cracks that accelerate chemical corrosion.

Rigid PVC Core Layer: Provides structural integrity and acts as a barrier against chemical penetration.

ASA Resin or Acrylic Modifiers (in some products): Further improve the sheets' resistance to fading, weathering, and surface oxidation.

These design choices create a roofing material capable of withstanding long-term exposure to corrosive gases, airborne salts, industrial emissions, and fertilizers commonly found in warehouses, markets, and coastal factories.

Unlike metal roofs that rust easily or fiber cement tiles that degrade over time, anti-corrosion PVC sheets require minimal maintenance to retain their integrity and appearance. This makes them an ideal solution for humid, corrosive, or poorly ventilated environments.

Calcium-Zinc Stabilizers: Added during production to replace toxic lead-based stabilizers, enhancing resistance to acid rain, ammonia, and high humidity.

UV-Resistant Outer Layer: Prevents surface degradation, which often leads to micro-cracks that accelerate chemical corrosion.

Rigid PVC Core Layer: Provides structural integrity and acts as a barrier against chemical penetration.

ASA Resin or Acrylic Modifiers (in some products): Further improve the sheets' resistance to fading, weathering, and surface oxidation.

These design choices create a roofing material capable of withstanding long-term exposure to corrosive gases, airborne salts, industrial emissions, and fertilizers commonly found in warehouses, markets, and coastal factories.

Unlike metal roofs that rust easily or fiber cement tiles that degrade over time, anti-corrosion PVC sheets require minimal maintenance to retain their integrity and appearance. This makes them an ideal solution for humid, corrosive, or poorly ventilated environments.

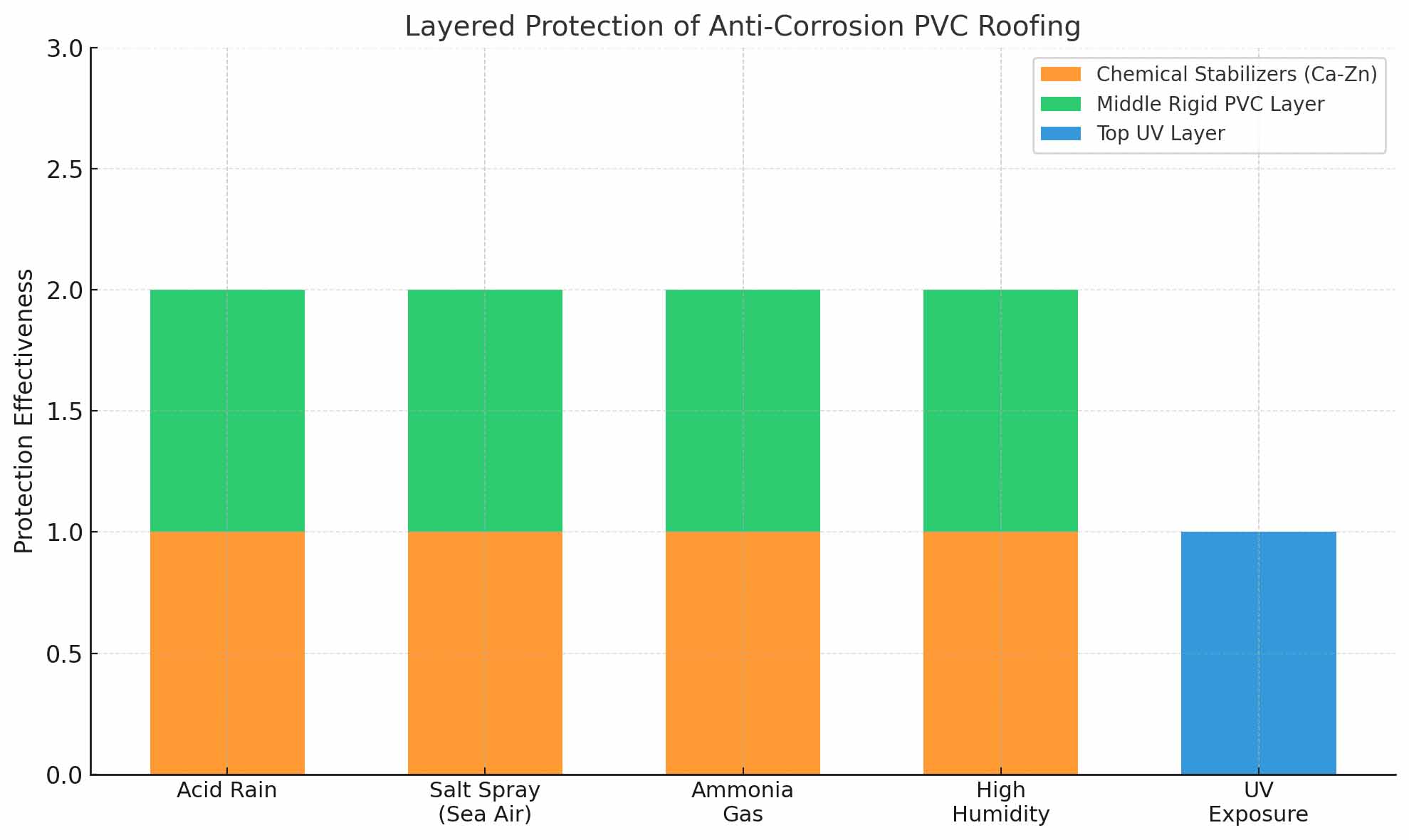

The diagram above illustrates how the three functional layers of anti-corrosion PVC roofing (UV-resistant top layer, rigid PVC core, and calcium-zinc stabilizers) work together to combat different environmental threats:

UV Radiation: Primarily blocked by the top UV-resistant layer, preventing surface degradation and fading.

Acid Rain, Salt Spray, Ammonia, and Humidity: Mitigated by the core PVC structure and chemical stabilizers, ensuring long-term structural integrity.

This layered defense mechanism explains why these roofing sheets are widely used in coastal, chemical, and agricultural environments where traditional roofing materials would quickly fail.

UV Radiation: Primarily blocked by the top UV-resistant layer, preventing surface degradation and fading.

Acid Rain, Salt Spray, Ammonia, and Humidity: Mitigated by the core PVC structure and chemical stabilizers, ensuring long-term structural integrity.

This layered defense mechanism explains why these roofing sheets are widely used in coastal, chemical, and agricultural environments where traditional roofing materials would quickly fail.

3. Practical Applications: Where Is It Most Commonly Used?

Anti-corrosion PVC roofing is designed for environments requiring durability, chemical resistance, and long-term stability. Its versatility makes it suitable for various industrial and commercial buildings, particularly in developing regions with tropical or coastal climates.

Here are some of the most common applications:

Here are some of the most common applications:

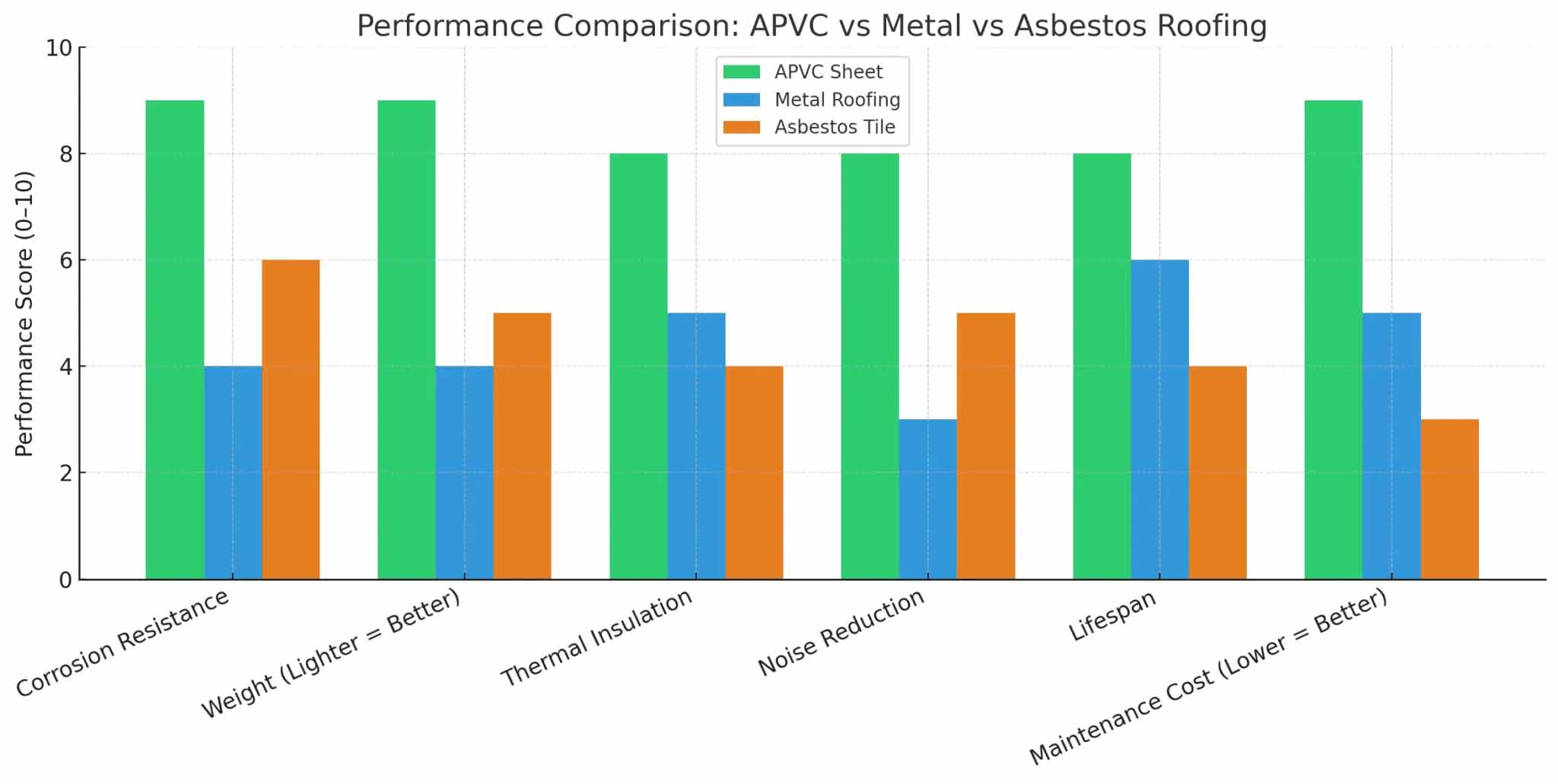

4. Why Choose UPVC Roof Sheet Over Metal or Asbestos Alternatives?

When selecting roofing materials for industrial or commercial use, many buyers still consider metal sheets or asbestos tiles due to their familiarity or lower upfront costs. However, these materials often have long-term drawbacks in today's construction environment.

Here’s how anti-corrosion PVC roofing compares:

Corrosion Resistance: Unlike metal roofs, which are prone to rust and damage from salt spray and acidic fumes, UPVC roofing resists chemical erosion without requiring painting or surface treatments.

Weight and Structural Load: UPVC sheets are significantly lighter than metal or asbestos, reducing structural stress and simplifying transportation and installation, especially for large-span steel structures or temporary buildings.

Thermal and Acoustic Insulation: UPVC provides superior insulation, helping to lower internal temperatures and create quieter environments—critical for markets, warehouses, and workshops.

Maintenance and Lifespan: Metal roofs may require periodic repainting or sealing, while asbestos tiles degrade over time and pose health risks. In contrast, UPVC roofing requires almost no maintenance and can remain stable for 15–25 years, depending on conditions.

Environmental and Safety Considerations: Asbestos is banned or restricted in many countries due to health hazards. UPVC is a lead-free, recyclable material that aligns with modern safety and environmental standards.

While metal and asbestos roofing still have their place in historical contexts, anti-corrosion PVC roofing offers a smarter, longer-lasting solution for today's projects.

Here’s how anti-corrosion PVC roofing compares:

Corrosion Resistance: Unlike metal roofs, which are prone to rust and damage from salt spray and acidic fumes, UPVC roofing resists chemical erosion without requiring painting or surface treatments.

Weight and Structural Load: UPVC sheets are significantly lighter than metal or asbestos, reducing structural stress and simplifying transportation and installation, especially for large-span steel structures or temporary buildings.

Thermal and Acoustic Insulation: UPVC provides superior insulation, helping to lower internal temperatures and create quieter environments—critical for markets, warehouses, and workshops.

Maintenance and Lifespan: Metal roofs may require periodic repainting or sealing, while asbestos tiles degrade over time and pose health risks. In contrast, UPVC roofing requires almost no maintenance and can remain stable for 15–25 years, depending on conditions.

Environmental and Safety Considerations: Asbestos is banned or restricted in many countries due to health hazards. UPVC is a lead-free, recyclable material that aligns with modern safety and environmental standards.

While metal and asbestos roofing still have their place in historical contexts, anti-corrosion PVC roofing offers a smarter, longer-lasting solution for today's projects.

5. Purchasing Guide: What to Check Before Selecting UPVC Roofing

While anti-corrosion PVC roofing offers significant technical advantages, not all UPVC sheets are of equal quality. Differences in formulation, production techniques, and quality control can lead to notable variations in performance.

Before purchasing, B2B buyers should consider the following:

Layer Structure: High-quality UPVC roofing typically features a three-layer co-extruded structure, including a UV-resistant top layer, rigid PVC core, and stabilizers. Request cross-section samples or third-party test reports.

Material Sources: Virgin (non-recycled) PVC with calcium-zinc stabilizers ensures better corrosion resistance and safety. Be cautious of overly cheap sheets, as they may contain recycled materials or heavy metal additives.

Thickness Range: Different applications require different thicknesses. For large-span industrial buildings, sheets between 2.0mm and 3.0mm are recommended to ensure mechanical strength and wind resistance.

Fireproof Certification: For commercial spaces, especially warehouses or markets, fire resistance is crucial. Choose UPVC sheets with a flame-retardant rating of B1 or higher.

Manufacturer Reputation and Experience: Select suppliers with proven export experience, factory-level production control, and technical support. Long-term performance depends not only on product quality but also on after-sales service and delivery efficiency.

Before purchasing, B2B buyers should consider the following:

Layer Structure: High-quality UPVC roofing typically features a three-layer co-extruded structure, including a UV-resistant top layer, rigid PVC core, and stabilizers. Request cross-section samples or third-party test reports.

Material Sources: Virgin (non-recycled) PVC with calcium-zinc stabilizers ensures better corrosion resistance and safety. Be cautious of overly cheap sheets, as they may contain recycled materials or heavy metal additives.

Thickness Range: Different applications require different thicknesses. For large-span industrial buildings, sheets between 2.0mm and 3.0mm are recommended to ensure mechanical strength and wind resistance.

Fireproof Certification: For commercial spaces, especially warehouses or markets, fire resistance is crucial. Choose UPVC sheets with a flame-retardant rating of B1 or higher.

Manufacturer Reputation and Experience: Select suppliers with proven export experience, factory-level production control, and technical support. Long-term performance depends not only on product quality but also on after-sales service and delivery efficiency.

6. Smarter Construction, Longer Lifespan: Why UPVC Is More Than Just Roofing

From its multi-layer anti-corrosion structure to its long-term durability, recyclable formulation, and cost-effectiveness, anti-corrosion PVC roofing (commonly known as UPVC) is no longer a niche product. It has become the go-to roofing solution for industrial and commercial projects in emerging markets.

Whether you're building a logistics warehouse in Africa, upgrading a steel-structure factory in Southeast Asia, or seeking low-maintenance roofing for public market corridors, UPVC roofing delivers a rare balance of performance, safety, and sustainability.

As a professional UPVC roof sheets manufacturer from China, SY/Uniko ROOF specializes in manufacturing and exporting high-quality UPVC roofing sheets, offering full customization options, export documentation, and technical support. We collaborate with construction contractors, distributors, and importers across Asia, Africa, and the Middle East.

Contact us today for free samples, detailed specifications, or wholesale inquiries. Let’s work together to build better, longer-lasting roofs.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

Installation Instructions of UPVC & ASA Synthetic Resin Roof Sheet

Installation Instructions of UPVC & ASA Synthetic Resin Roof Sheet