Why Do ASA Roof Tiles Develop Cracking and Discoloration?

Sep 03,2025

Sep 03,2025

Shenyu

Shenyu

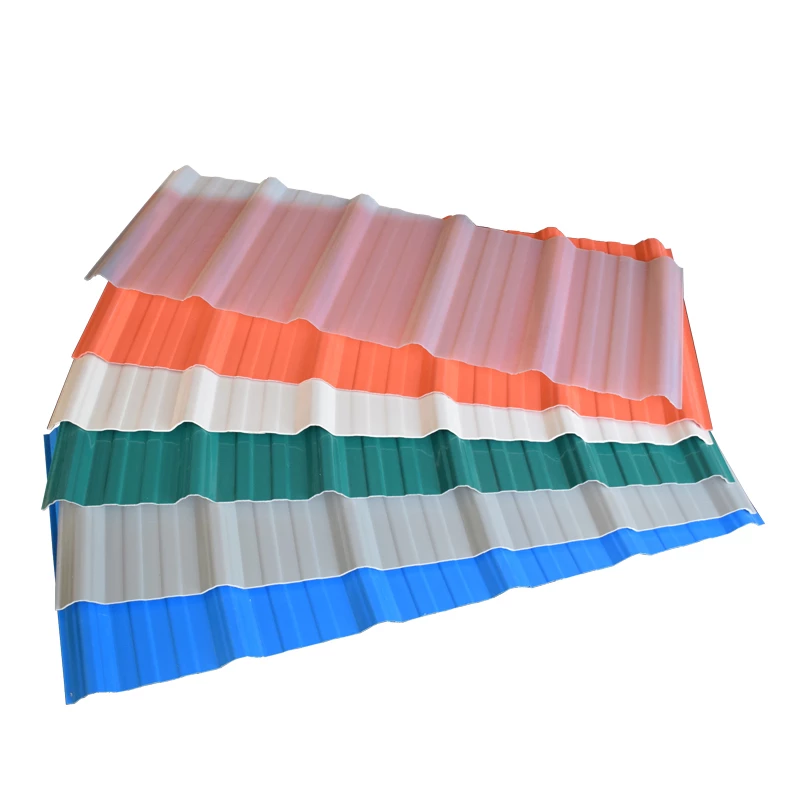

In modern construction, ASA resin roof tiles have become a top choice for roofing due to their lightweight, durable, and aesthetically pleasing properties. However, many users report that some ASA roofing sheets develop cracking, fading, and other quality issues within just a year of installation. Not only does this affect the visual appeal, but it also significantly shortens the product's service life. So, what causes these problems? And how can they be avoided?

Problem 1: Fading and "Color Striping"

Many users notice that low-cost synthetic resin roof tiles fade noticeably in a short time, and some even develop uneven color patches—a phenomenon often called "color striping." The root causes include:

- Substandard ASA Layer: High-quality ASA resin roof tile products should have a sufficiently thick surface layer of ASA (Acrylonitrile-Styrene-Acrylate) engineering plastic, which is essential for UV resistance and color retention. However, many inferior products have an ASA layer that is less than one-third the thickness required by national standards and unevenly distributed, failing to block UV radiation effectively.

- Use of Inferior ASA Material: Some manufacturers use low-quality or recycled ASA to reduce costs, significantly compromising weatherability and color stability.

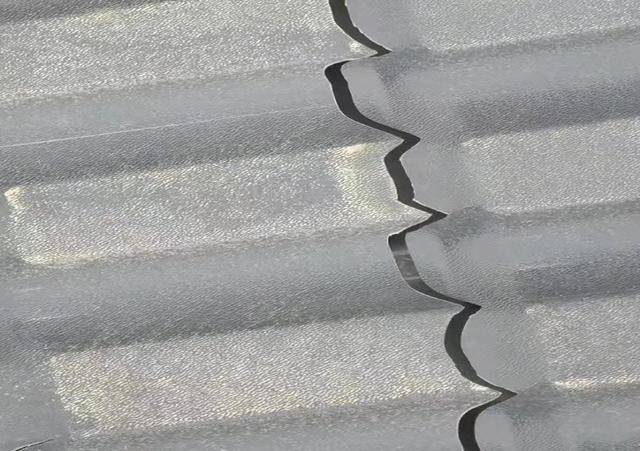

Problem 2: Cracking and Deformation

Cracking is another common issue with ASA PVC roof tile products, especially in regions with large temperature variations. The main reasons are:

- Excessive Calcium Carbonate Filler: To cut costs, some producers add too much calcium powder to the PVC base material, which reduces the tile’s flexibility and weather resistance, leading to cracking and deformation during thermal expansion and contraction.

- Poor Raw Material Quality: The use of recycled or inferior PVC resin with unstable molecular structure greatly diminishes impact resistance and low-temperature performance.

The Low-Price Trap: Balancing Cost and Quality

Many customers are attracted by low prices when selecting resin roof tiles, believing that “high quality at low cost” is achievable. However, the rule of “you get what you pay for” always applies. Lower prices often come with compromises in materials and production techniques, such as:

- Reducing the thickness of the ASA layer;

- Adding excessive calcium powder;

- Using recycled materials or inferior additives.

Although these practices reduce costs, they sacrifice the product’s durability and reliability, leading to premature quality issues.

SY/Uniko ROOF: Building Trust Through Quality

Amid market inconsistencies, SY/Uniko ROOF adheres to a “quality-first” philosophy. We do not engage in “one-time deals” but aim to earn long-term trust through reliable products. Our ASA synthetic resin roof tile products feature:

- Virgin high-weatherability ASA material with a surface layer that meets and exceeds national standards;

- Pure virgin PVC base material without excessive calcium filler;

- Multi-layer co-extrusion technology ensuring strong bonding between the ASA layer and the substrate;

- Strict quality control, with each batch tested for weather resistance, impact resistance, and more.

Thanks to these measures, SY/Uniko ROOF’s products maintain color stability, resist cracking, and avoid deformation even in high-UV and high-temperature-difference environments.

How to Avoid Low-Quality Resin Roof Tiles?

As professional roofing solution providers, we offer multiple advantages: stringent quality control systems ensure every product meets highest standards; 10-30-year product quality guarantee provides customer assurance; extensive global project experience handles complex requirements; strong customization capabilities satisfy special project needs.

- Check the ASA Layer Thickness: High-quality ASA resin tiles should have a uniform and sufficiently thick ASA layer.

- Verify Material Composition: Request material test reports from manufacturers to avoid products with excessive calcium powder or recycled content.

- Choose a Reputable Brand: Such as SY Roof Tile/Uniko ROOF, which has a robust quality assurance system and long-term market reputation.

- Prioritize Warranty and Service: Reliable manufacturers typically offer warranties of 10 years or more.

Conclusion

Cracking and discoloration of ASA synthetic resin roof tiles are not inherent flaws of the material but result from short-sighted practices of some manufacturers. By choosing ASA roofing sheet products that comply with standards and use solid materials, users can achieve a long-lasting, attractive, and reliable roofing solution. SY/Uniko ROOF is committed to providing high-quality products and professional service to protect your buildings.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

How ASA Synthetic Resin Roof Tiles Protect Your Factory Against Super Typhoons

How ASA Synthetic Resin Roof Tiles Protect Your Factory Against Super Typhoons