14 Roofing Materials & Costs: Best Options for Projects (2025 Guide)

Jul 31,2025

Jul 31,2025

Shenyu

Shenyu

Choosing the right roofing material is no longer just about aesthetics or price—it's a strategic investment decision. In today's construction industry, with increasingly tight schedules, hotter climates, and higher quality requirements, procurement teams and contractors must weigh durability, installation efficiency, logistics, and long-term performance. This is especially true in tropical, coastal, and high-UV regions, where the selection of roofing materials directly impacts project profitability and reputation.

This guide will explore 14 commonly used roofing materials from a practical perspective, evaluating them based on cost-effectiveness, suitability for export markets, and long-term value. Whether you're procuring materials for a warehouse project in Southeast Asia, a public school tender, or a commercial facility in a coastal area, the following information will help you align product selection with business outcomes.

14 Common Roofing Materials: Features and Estimated Costs

1. Clay Roof Tiles

Clay tiles are widely recognized for their high-end appearance and long-lasting durability. For distributors targeting government tenders, real estate developers, or municipal contractors, clay tiles are a high-value upsell product with consistent demand in public and institutional projects. Although logistics costs are high, the retail price per square meter supports healthy profit margins, especially in high-end or renovation projects. Clay tiles are also an ideal addition to any product catalog focused on historical or luxury buildings, helping you diversify your offerings and strengthen your position in the premium market.

2. Concrete Roof Tiles

Concrete tiles offer the look of traditional materials at a more affordable price. This makes them a top choice for volume-driven projects such as residential communities, schools, or commercial plazas. For B2B suppliers, they serve as a mid-range product that balances profitability and mass-market appeal. While heavier in weight, their stable performance and ease of procurement make them well-suited for urban development projects where both cost and appearance matter. Offering concrete tiles allows your business to bid on projects that require cost-effective roofing solutions without sacrificing visual standards.

3. Metal Roofing Sheets (Aluminum, Zinc, Galvanized Steel)

Metal roofing is one of the most efficient materials for industrial and logistics-related buildings. These sheets are easy to store, transport, and install, and they offer excellent durability in tropical and coastal regions. For distributors and project buyers, metal sheets enable high turnover and bulk sales—especially in industrial parks, storage clusters, and agricultural facilities. Since these projects often require fast construction timelines, they generate repeat orders quickly, making them ideal for large-scale procurement contracts.

4. Asphalt Shingles

Asphalt shingles are particularly attractive for cost-conscious residential projects or buyers in the DIY retail sector. They are easy to transport and store and can be marketed as a quick-install roofing option for temporary or semi-permanent structures. While less durable than other options, their appeal lies in high-volume sales at competitive profit margins, making them ideal for distributors serving housing cooperatives, prefab construction suppliers, or low-income housing markets. If your customers prioritize flexibility and speed over long-term performance, this product can rapidly increase your order volume.

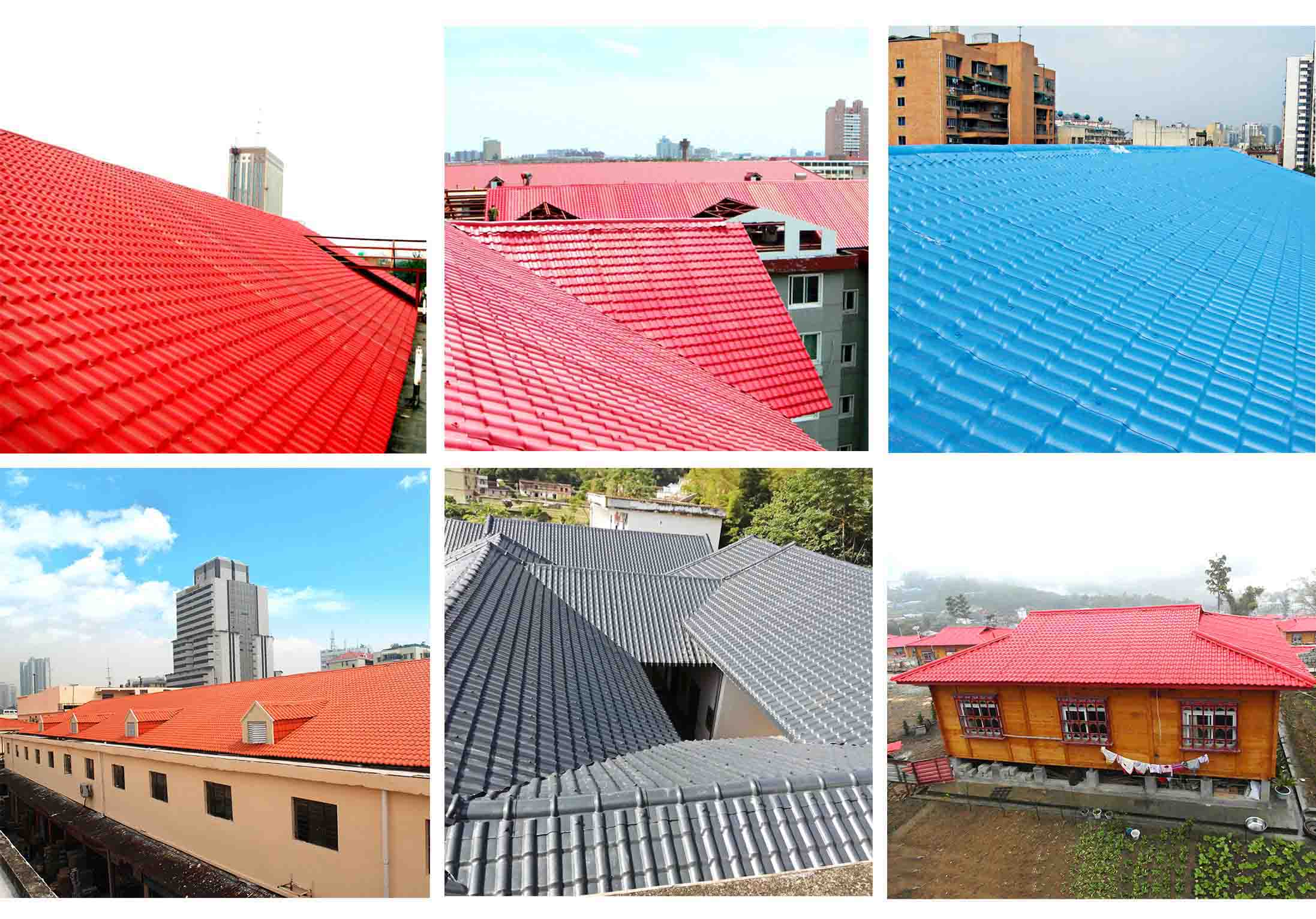

5. Synthetic Resin Roofing Tiles (ASA-PVC by SY/UNIKO ROOF)

SY/UNIKO ROOF’s ASA synthetic resin tiles are specifically designed for regions with intense UV exposure, high humidity, and chemical corrosion, such as Southeast Asia and the Middle East. For contractors and distributors, these tiles offer one of the best combinations of performance, shipping efficiency, and market fit. Their lightweight structure reduces transportation and labor costs, while their color stability and corrosion resistance significantly lower maintenance needs, making them highly attractive for industrial and public building bids. Additionally, full OEM/ODM customization support allows distributors to create their own branded products with a premium positioning. These tiles are among our most popular export products, achieving resale success in both private-sector warehouses and government-funded developments.

6. Asphalt Corrugated Sheets

Asphalt sheets are an entry-level solution, well-suited for rural infrastructure, farms, and budget-driven projects. Their key advantages include high shipping density and quick installation, enabling distributors to handle large volumes with minimal operational complexity. They are ideal for distributors targeting agricultural supply chains or markets with seasonal housing needs. While this product has a shorter lifecycle, it offers strong cash flow potential through repeat small-scale purchases. Many of our Southeast Asian buyers use this product to expand their price-sensitive customer base while maintaining profitability through volume.

7. Slate Roofing

Slate is a premium natural roofing material with unmatched aesthetic appeal and durability—often lasting over 100 years. For suppliers targeting luxury real estate, embassy projects, or historical restoration, slate not only carries high unit value but also elevates the prestige of your product lineup. Although shipping and handling costs are high, the per-unit profit margins can be substantial, and its uniqueness helps it stand out in VIP client or government-approved restoration project catalogs. Adding slate to your product range allows you to better serve clients who prioritize long-term performance over budget constraints.

8. Wood Shakes

Wood shakes offer a rustic, natural appearance that appeals to resort construction, eco-home developments, and boutique hotel projects. While they require more maintenance than synthetic materials, their charm and insulation properties are valued in specific architectural contexts. For distributors, this product represents a niche, high-margin opportunity—especially for designers or project contractors seeking sustainability or traditional styling. Wood shakes are an ideal addition to curated catalogs, helping build credibility with architects and private developers.

9. Solar Roof Panels

Solar roofs combine structural protection with electricity generation. Driven by green energy policies and rising energy costs, this category is growing rapidly. Although the initial investment is higher, for B2B suppliers involved in government-led green projects, commercial buildings, or industrial parks, solar roofs offer a high-margin, future-proof product. If your clients are committed to sustainable development, offering solar panels will position your company as a forward-thinking, high-tech solutions provider and open new funding-supported procurement channels.

10. Thatch Roofing (Natural or Synthetic)

Thatch roofs provide a tropical cultural aesthetic, attracting resort owners, cultural centers, and leisure buildings. Synthetic thatch options reduce fire risks and enhance durability, making them suitable even in urbanized tourist areas. For your business, this material offers differentiation through style-specific projects—especially in Southeast Asia’s booming eco-tourism sector. It caters to design-driven clients with high customization budgets and can achieve strong markup when paired with installation guidance and sample support.

11. Green Roof Systems (Eco Roofs)

Green roofs are soil-based systems that support plant growth on structures, designed for urban cooling, sustainability, and reduced environmental impact. While installation requires specialized support and structural assessment, these systems are often subsidized by governments or international green building initiatives. For suppliers, green roofs represent a high-value product category with strong branding benefits—successful even at lower sales volumes. Ideal for buyers linked to urban planning departments or smart city projects, this material helps position your company as a participant in climate-oriented construction.

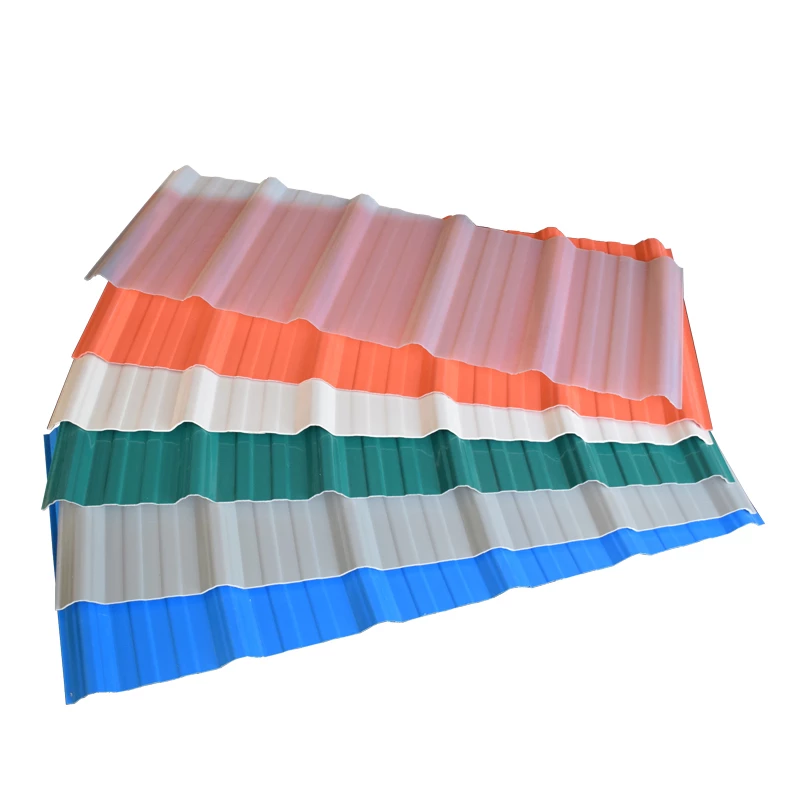

12. Plastic Roof Panels (Flat and Corrugated PVC)

Plastic roof panels, particularly corrugated PVC roof sheets, are valued for their light transmission, corrosion resistance, and ultra-light weight. Commonly used in agricultural warehouses, greenhouses, carports, and low-spec workshops, they offer fast turnover and high shipping efficiency. For importers and wholesalers, they are easy to stock, simple to cut on-site, and adaptable to various climates. This product is best suited for fast-paced B2B environments where volume and logistics savings are critical. It also serves as an excellent entry-level product for first-time buyers exploring alternative roofing solutions.

13. Fiber Cement Roofing Sheets

Fiber cement sheets are sturdy and pest-resistant, combining the durability of cement with the versatility of panel installation. For clients involved in rural housing projects, farm buildings, or low-rise commercial roofs, they provide a good balance between performance and price. They are particularly effective where fire resistance and anti-biological degradation are crucial. Distributors offering fiber cement can tap into budget-conscious public or agricultural projects where safety and longevity outweigh design aesthetics.

PVC Hollow Roof Sheets are a cost-effective, multi-purpose roofing material designed for industrial, agricultural, and temporary structures. Their hollow polygonal structure provides excellent thermal insulation, noise reduction, and weather resistance, making them ideal for:

Warehouses & Factories – UV-stabilized to withstand sun exposure

Greenhouses & Farms – High light transmission (up to 85%) for plant growth

Parking Shades & Canopies – Lightweight yet strong (wind & impact resistant)

Temporary Shelters – Easy to install, dismantle, and relocate

Why Roofing Material Choice Affects ROI

In the roofing industry, product decisions are not just about appearance—they impact economic efficiency, service life, and risk control. This is especially evident in tropical and high-rainfall regions, where poor roofing choices lead to faster deterioration, water damage, and increased long-term maintenance costs.

Based on our manufacturing and export experience in Southeast Asia and the Middle East, we’ve seen how the wrong roofing materials—even if cheaper upfront—can significantly raise total ownership costs. Humidity, salty air, intense UV radiation, and monsoons accelerate material aging, making durability a core factor in ROI for contractors, government tenderers, housing developers, and warehouse operators alike.

When procurement teams select materials for public infrastructure, school projects, industrial parks, or farm buildings, they need more than surface-level product specs. They require materials that reduce installation time, lower structural load, resist corrosion, and minimize future repairs. These aren’t just preferences—they’re necessities for staying on budget, passing inspections, and outlasting warranty periods.

SY/UNIKO ROOF specializes in roofing materials engineered for these demanding conditions. For example, our ASA synthetic resin tiles have been used in coastal factory zones in Indonesia and high-rainfall logistics centers in the Philippines. Compared to traditional metal or cement tiles, clients report over 40% fewer post-installation complaints—especially in regions with prolonged rainy seasons. It’s not just about price per square meter but real-world annual performance costs.

Who This Guide Is For:

Bulk buyers balancing order volume and container efficiency

Distributors and importers selling to weather-affected regions

Construction contractors bidding on projects where durability is a deciding factor

Government procurement teams sourcing certified, long-life materials

Private developers building reputations on quality rather than callbacks

Each material covered in this guide reflects factory insights and real customer feedback. If you’re responsible for specifying or procuring roofing solutions, your decisions will influence not just profits but also customer satisfaction, corporate reputation, and future scalability.

Key Criteria for Evaluating Roofing Materials

Selecting the right roofing material isn’t just a technical choice—it’s a business decision. For bulk purchasers, project contractors, and building distributors, what matters most is how materials perform under real conditions, their procurement and installation efficiency, and the profitability they deliver after accounting for all project costs.

Drawing on over a decade of manufacturing and export experience in Southeast Asia and the Middle East, we recommend professional buyers assess roofing materials using these key factors:

1. Weather Resistance and UV Protection

In hot, humid markets, roofing must withstand year-round sun exposure, high temperatures, and sudden weather shifts. Materials that fade, crack, or warp under UV rays lose visual appeal and erode client confidence. That’s why SY/UNIKO ROOF’s ASA resin tiles incorporate UV-4 protection, ensuring color and shape stability even after years of intense sunlight.

2. Waterproofing and Corrosion Resistance

Coastal monsoons and salt-laden air accelerate decay in unprotected materials. Roofs lacking waterproof coatings or anti-corrosion properties lead to leaks, mold, and premature failure—forcing costly repairs. Products like PVC corrugated sheets and ASA resin tiles resist acid rain, salt spray, and moisture penetration, making them ideal for inland and coastal projects alike.

3. Weight and Ease of Installation

For contractors and importers, material weight affects far more than shipping costs. Heavy tiles require reinforced substructures, longer installation times, and larger crews. Lightweight options like ASA resin tiles or PVC sheets reduce transport and labor costs by up to 30%, directly boosting profits and accelerating project timelines.

4. Lifespan and Maintenance Costs

A roof’s true cost isn’t its upfront price but its service life before replacement or repairs. A tile that lasts 20 years without maintenance is far more profitable than one needing attention every five years. Field data from our buyers in Indonesia and the Philippines shows ASA resin tiles maintain stable performance for over a decade in coastal warehouses, with no fading or material degradation.

5. Export Readiness, Certifications, and Customization

B2B clients working on government or commercial projects need certified materials. At SY/UNIKO ROOF, we comply with SGS, CE, and ISO standards and provide detailed technical datasheets and installation guides with every shipment. We also offer custom branding, color matching, and OEM options—critical for distributors building private-label lines or meeting project-specific aesthetics.

What This Means for Buyers

If you’re a regional distributor minimizing inventory risk, a cross-border importer optimizing landed costs, or a contractor bidding on time-sensitive projects, these criteria aren’t optional—they’re essential. Materials meeting these principles reduce risk and enhance profitability across the supply chain.

Why Synthetic Resin Roofing Tiles Excel in Southeast Asia & Industrial Projects

For tropical, high-humidity, or high-salinity environments, synthetic resin roofing tiles outperform traditional materials in practicality and performance. Their advantages aren’t theoretical—they’re proven in real-world projects across Southeast Asia, where long-term durability, shipping efficiency, and cost control determine construction profitability.

1. Tropical-Tested Durability

In Indonesia, the Philippines, Vietnam, and Malaysia, constant exposure to UV rays, heavy rain, and temperature fluctuations can destroy unprotected roofs within years. Unlike corrosion-prone metal or stain-vulnerable cement, ASA-PVC resin tiles resist UV damage, maintain structural integrity, and retain color for over a decade.

Clients using SY/UNIKO ROOF’s ASA tiles in coastal warehouses and school buildings report minimal surface chalking or brittleness even after five+ years of tropical conditions. This avoids repair costs while protecting reputations and instilling confidence in large-scale infrastructure delivery.

2. Lightweight = Lower Transport & Installation Costs

Weight matters in bulk supply. Resin tiles are far lighter than clay, concrete, or fiber cement, allowing more coverage per container, reduced structural load, and faster installation with smaller crews. For project managers, this means lower freight expenses, streamlined logistics, and quicker construction—critical for public tenders or phased developments.

3. Ideal for Warehouses, Schools, Factories & Low-Maintenance Facilities

Resin roofing’s performance suits any project demanding durability, minimal upkeep, and 10–15-year lifecycle cost control. SY/UNIKO ROOF’s tiles are widely used in:

Factories exposed to chemical fumes or sea air

School buildings prioritizing safety, noise reduction, and color retention

Affordable housing and logistics facilities

Agri-processing plants and rural storage sites

Whether your clients are building in coastal cities or humid inland tropics, resin roofing delivers the balance of price, performance, and ease-of-use they need.

4. Compliance & Trust for B2B Buyers

SY/UNIKO ROOF’s ASA resin tiles range from 2.0mm to 3.5mm in thickness, with single/multi-layer (insulated) options. All materials meet CE, ISO, and SGS standards, ensuring smooth approvals for international and government-regulated projects.

We provide full technical documentation, installation guides, and OEM/ODM customization—from color and profile design to private labeling. Whether you’re a regional distributor building a branded line or a contractor bidding on bulk government tenders, we support large-scale production and service needs.

Ideal Buyers for This Product

If you’re a:

Building materials distributor supplying climate-sensitive markets

Cross-border importer managing container loads and seeking volumetric efficiency

Industrial contractor or engineering firm bidding on factory, school, or warehouse projects

Procurement team working under government frameworks or strict compliance requirements

…then resin roofing tiles aren’t just a product—they’re a long-term solution to common roof failures and a cost-saving upgrade for your clients.

Cost Structures & Supply Factors for Bulk Purchases

For large-scale roofing buyers—whether importing by container or planning public infrastructure—a product’s true value extends beyond per-square-meter pricing. It includes total landed costs, inventory management ease, and alignment with project/regulatory needs. At SY/UNIKO ROOF, we collaborate closely with Southeast Asian and Middle Eastern procurement teams to optimize these variables.

1. Shipping Costs & Import Duties Vary by Region & Strategy

One often-overlooked variable in roofing procurement is hidden cost erosion during shipping and customs. Heavy materials like clay and concrete quickly eat into profits once ocean freight, inland transport, and tariffs are factored in. Lightweight options like ASA resin tiles and PVC corrugated sheets slash per-unit shipping costs, especially when efficiently loaded into HQ containers.

For example, in a recent shipment to Port Klang, Malaysia, we increased roof area per container by 30% versus fiber cement alternatives while reducing unloading damage via palletized, corner-reinforced packaging. For distributors, this means lower landed costs and greater inventory flexibility at sales points.

2. Flexible MOQs & Packaging for Trade Efficiency

SY/UNIKO ROOF understands not all buyers place mega-orders. We offer soft MOQs starting at 3,000㎡ for standard products, with negotiable quantities for custom specs. Products are packed in stretch film, export-grade pallets, and stackable configurations to protect tile finishes and shapes during transit.

For overseas clients managing multiple SKUs, we also provide mixed-container loads, letting you combine resin tiles with PVC sheets, ridge caps, or waterproofing accessories—maximizing logistics ROI without bloating inventory.

3. Custom Branding, Color Matching & Spec Flexibility

Many of our buyers are private-label distributors or contractors adhering to branded construction standards. For them, we offer OEM/ODM customization: tile profiles, thickness (2.0mm–3.5mm), and surface colors can all be tailored. Whether your client needs UV-blocking terracotta-red tiles for local housing or blue-gray tiles for government warehouses, we match Pantone colors, apply protective coatings, and even emboss logos directly onto tile contours.

Our in-house tooling team ensures fast mold turnover, while QC provides pre-shipment samples and color approvals—so you know exactly what’s arriving before the first container leaves port.

4. Budget Planning for Commercial & Government Projects

Working with clients on Indonesian public school roofs and Philippine social housing, we’ve seen how roofing costs influence not just approvals but contract wins. A project saving 15% on materials and labor (without compromising compliance) can bid more competitively, freeing funds for insulation, solar integration, or extended warranties.

To support your budgeting, we provide:

Detailed quotes with FOB/CIF pricing by region

Unit weights and container load specs for freight modeling

Installation guides and lifespan projections for TCO (Total Cost of Ownership) analysis

Performance certifications (CE, ISO, SGS) to streamline regulatory approvals

Who Should Care About These Supply Factors?

If you’re a:

Cross-border importer managing shipping budgets and customs

Distributor seeking low-MOQ entry points with private-label options

Contractor estimating materials/labor for mid- to national-scale projects

Government buyer balancing cost targets with public-sector performance standards

…then these aren’t minor details—they dictate your profits, delivery timelines, and end-user satisfaction.

Conclusion

Today, roofing procurement isn’t about comparing price lists—it’s about real-world performance, logistics viability, resale margins, and local compliance. Based on SY/UNIKO ROOF’s decade of exporting to Southeast Asia and the Middle East, this guide analyzes 14 major roofing materials, covering durability, weight, certifications, installation advantages, and OEM potential. Each section helps B2B buyers quickly identify products matching their needs, whether for factories, schools, agricultural buildings, or municipal tenders.

If you seek roofing materials that are competitively priced, compliant, efficiently shipped, and brand-ready, this guide will shorten procurement cycles and boost project success. The right choice elevates profitability, reduces returns, and unlocks scalable growth.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

The Science Behind Strength: A Comprehensive Exploration of UPVC Roof Sheets' Engineering Principles

The Science Behind Strength: A Comprehensive Exploration of UPVC Roof Sheets' Engineering Principles