The Science Behind Strength: A Comprehensive Exploration of UPVC Roof Sheets' Engineering Principles

Aug 03,2025

Aug 03,2025

Shenyu

Shenyu

When discussing roofing and cladding solutions, strength and durability stand as paramount considerations for every builder and architect. SY/Uniko ROOF's UPVC roof sheets represent the pinnacle of modern engineering technology, offering not just basic protection but exceptional long-term performance even in the most demanding environmental conditions. But what exactly gives these UPVC roof tiles their remarkable strength and reliability? The secret lies in the sophisticated science behind - where advanced material composition meets precision manufacturing processes to deliver unparalleled resilience and performance.

In this in-depth technical guide, we will thoroughly examine the scientific principles underlying UPVC roof panels, exploring their material composition, manufacturing techniques, and structural advantages that make them the intelligent choice for industrial, commercial, and residential roofing applications worldwide.

Understanding UPVC: The Superior Material Choice

UPVC (Unplasticized Polyvinyl Chloride) is a rigid form of PVC that contains absolutely no phthalates or plasticizers, making it significantly more robust, durable, and resistant to chemical corrosion than standard materials. Thanks to its exceptional structural integrity, UPVC sheets have become indispensable in modern construction, particularly for window frames, door systems, and advanced roofing solutions.

Unlike conventional PVC roof sheets, UPVC roof tiles demonstrate superior resistance to bending and deformation, offering distinct advantages in terms of mechanical strength, weather resistance, and overall lifespan. This makes UPVC roofing sheets the preferred choice for projects requiring long-term performance with minimal maintenance.

The outstanding strength characteristics of UPVC roofing sheets stem from carefully engineered material properties that maintain optimal performance under various stress conditions:

1. Superior Impact Resistance

Engineered UPVC roof panels are specifically designed to withstand significant impacts from falling debris, hailstorms, and even limited human traffic. This remarkable durability is achieved through the strategic incorporation of impact modifiers during the manufacturing process, which significantly enhance the material's structural integrity and elastic recovery properties.

2. Outstanding Thermal Stability

With an inherently low thermal conductivity coefficient, UPVC roof sheets provide excellent thermal insulation while maintaining dimensional stability across a wide temperature range. Specialized heat stabilizers are added to the formulation to ensure consistent performance even under intense solar radiation and extreme temperature fluctuations.

3. Unmatched Corrosion Resistance

One of the most significant advantages of UPVC roofing sheets is their complete immunity to corrosion, particularly valuable in coastal regions or industrial areas with chemical exposure. Unlike metal roofing alternatives, UPVC roof tiles will never rust or oxidize, maintaining their structural integrity for decades.

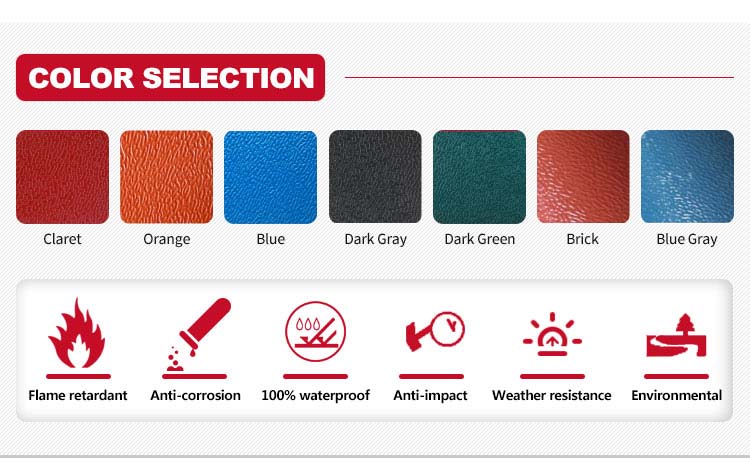

4. Advanced UV Protection

The incorporation of titanium dioxide (TiO₂) and specialized UV stabilizers during production ensures that UPVC sheets maintain their color stability and mechanical properties even after prolonged sun exposure, preventing the yellowing, embrittlement, and strength degradation common in inferior materials.

Manufacturing Excellence: The Precision Engineering Behind UPVC Roof Sheets

At SY/Uniko ROOF, our UPVC roofing sheets are manufactured using state-of-the-art extrusion technology. Here's a detailed look at our meticulous production process:

1. Precision Material Compounding

We begin by thoroughly blending premium UPVC resin with carefully selected additives including:

-High-performance impact modifiers

-Advanced UV stabilizers

-Thermal stabilizers

-Premium color pigments

-Processing aids

This mixture is homogenized under precisely controlled temperature conditions to ensure perfect dispersion and consistent material properties throughout every batch.

2. Precision Extrusion Process

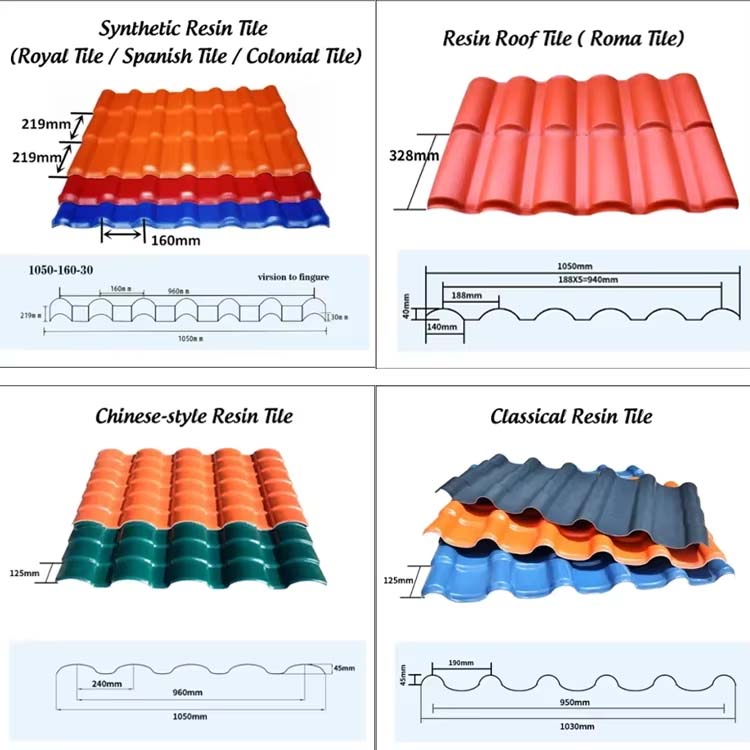

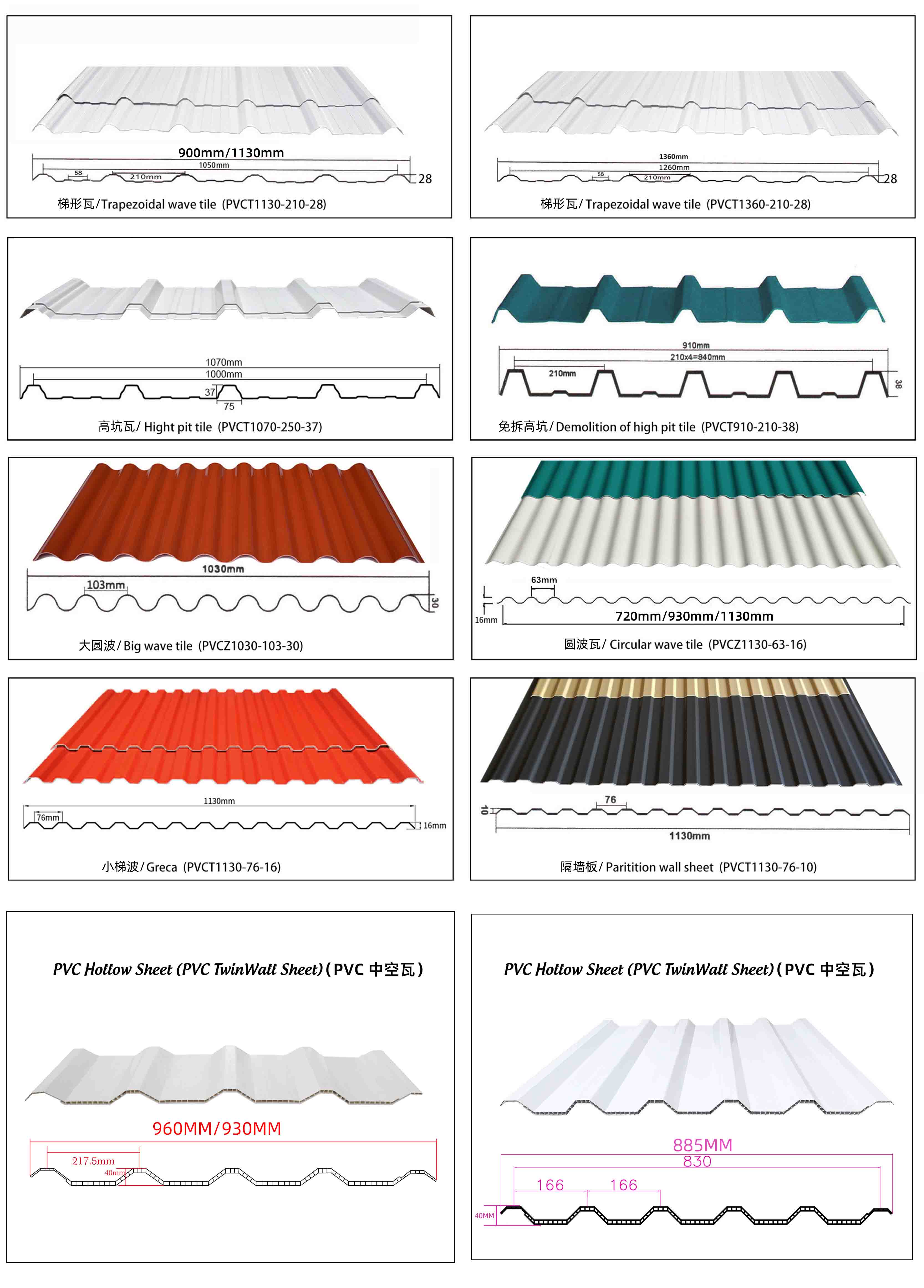

The compounded material is fed into our advanced extrusion systems where it is melted and forced through specially engineered dies. This allows us to create the exact profiles needed for various roofing applications - whether corrugated, trapezoidal, or custom-designed configurations to meet specific architectural requirements.

3. Controlled Cooling and Solidification

The extruded profiles undergo carefully calibrated cooling processes using either water baths or air cooling systems. This critical step ensures proper crystallization of the material while eliminating internal stresses that could compromise long-term performance.

4. Precision Cutting and Surface Finishing

After cooling, each UPVC roof panel is precisely cut to specified lengths and undergoes surface treatments that may include:

-Anti-static coatings

-Textured finishes

-Protective films

-Custom embossing

These finishing touches enhance both the aesthetic appeal and functional performance of the final product.

Structural Engineering Innovations in UPVC Roof Tiles

The strength of UPVC roofing sheets isn't solely derived from their material composition - intelligent structural design plays an equally crucial role:

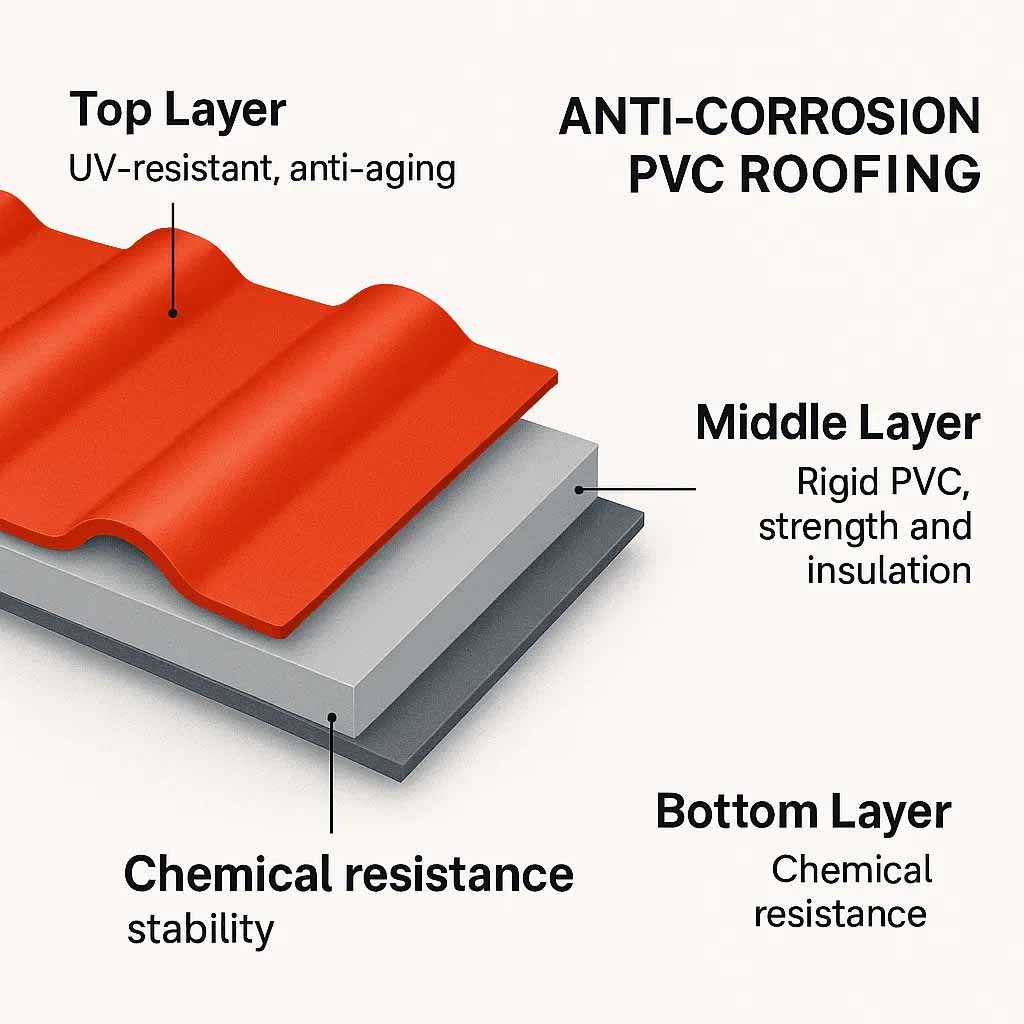

1. Multi-Layer Construction Technology

Many of our UPVC roof tiles feature sophisticated multi-layer designs where each stratum serves a specific purpose:

-Top Layer: UV protection and color stability

-Core Layer: Structural reinforcement and load-bearing capacity

-Base Layer: Additional insulation and interior finish

This layered approach optimizes weight distribution, thermal performance, and visual appeal.

2. Advanced Profile Engineering

The characteristic corrugated or trapezoidal patterns seen in UPVC roof sheets aren't merely aesthetic choices - they represent carefully calculated structural enhancements that:

-Increase load-bearing capacity

-Improve resistance to bending moments

-Enhance water drainage

-Optimize wind load resistance

3. Rigorous Quality Assurance

Every UPVC roofing sheet from SY/Uniko ROOF undergoes comprehensive testing including:

-Static load testing

-Tensile strength evaluation

-Impact resistance assessments

-Weathering simulations

These tests ensure compliance with both Indian IS standards and international benchmarks for quality and performance.

Whether facing the scorching heat of Rajasthan, the salty coastal air of Kerala, or the monsoon rains of Northeast India, UPVC roof panels consistently deliver reliable performance thanks to their resistance to:

-Extreme wind pressures

-Salt spray corrosion

-Torrential rainfall

-Intense UV radiation

-Industrial pollution

-Chemical exposure

This makes UPVC roofing sheets the ideal solution for:

-Manufacturing facilities

-Warehousing complexes

-Coastal residences

-Chemical processing plants

-Agricultural buildings

-Commercial structures

Environmental Sustainability: Combining Strength with Eco-Friendly Benefits

Beyond their mechanical advantages, UPVC roof sheets align perfectly with modern green building principles:

-100% Recyclable: Can be reprocessed multiple times without quality degradation

-Energy Efficient: Superior insulation reduces cooling requirements

-Non-Toxic: Contains no harmful plasticizers or heavy metals

-Low Carbon Footprint: Manufacturing process minimizes energy consumption

At SY/Uniko ROOF, we implement sustainable production practices that reduce emissions and optimize resource utilization throughout our manufacturing operations.

Why SY/Uniko ROOF Leads the UPVC Roofing Industry

At SY/Uniko ROOF, strength isn't just a feature - it's our fundamental standard. Here's why architects and builders across India consistently choose our UPVC roofing solutions:

-State-of-the-art manufacturing facilities

-Precision-engineered profiles

-Custom solutions for specialized requirements

-Exceptional durability with minimal maintenance

-Comprehensive technical support

-Industry-leading warranties

Whether you're roofing an industrial complex or a residential project, our UPVC roof sheets are engineered to deliver unmatched performance for decades to come.

Conclusion: The Science of Sustainable Strength

When you see UPVC roof tiles in use, remember that their lightweight appearance belies an extraordinary combination of materials science, structural engineering, and manufacturing precision. From molecular-level formulation to macro-scale design, UPVC roofing sheets represent the future of durable, sustainable roofing solutions.

As a leading UPVC roofing sheets manufacturer, SY/Uniko ROOF takes pride in pushing the boundaries of performance, delivering solutions that withstand both the test of time and the forces of nature.

Frequently Asked Questions

Q1: What specific materials are used in UPVC sheet production?

A: Our UPVC roof sheets primarily consist of high-grade polyvinyl chloride resin combined with specialized additives including impact modifiers, UV absorbers, thermal stabilizers, mineral fillers, and color pigments. Each component is carefully selected to enhance specific performance characteristics.

Q2: Can you elaborate on the extrusion process for UPVC roofing?

A: Our advanced extrusion process involves:

-Precise temperature-controlled melting of the UPVC compound

-High-pressure forcing through precision-engineered dies

-Multi-stage cooling for optimal crystallization

-Automated quality control checks throughout production

This ensures uniform thickness, perfect profile geometry, and consistent surface quality across all our UPVC roof panels.

Q3: How does the recyclability of UPVC sheets benefit the environment?

A: The closed-loop recyclability of UPVC roofing sheets offers multiple environmental advantages:

-Reduces landfill waste from construction debris

-Lowers demand for virgin raw materials

-Maintains material quality through multiple lifecycles

-Supports circular economy principles in construction

Q4: What are some specialized applications for UPVC sheets beyond standard roofing?

A: In addition to conventional roofing, our UPVC sheets are ideal for:

-Industrial wall cladding systems

-Noise barrier installations

-Cleanroom partitions

-Refrigeration facility enclosures

-Solar panel backing structures

-Modular building components

Each application benefits from UPVC's unique combination of strength, durability, and environmental resistance.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

Synthetic Spanish Roof Tiles Cost: A Key Consideration for Distributors, Contractors & Traders

Synthetic Spanish Roof Tiles Cost: A Key Consideration for Distributors, Contractors & Traders