Are ASA PVC Roof Sheets Really Not Heat Resistant? Unveiling Industry Truths & Buying Guide

Aug 27,2025

Aug 27,2025

Shenyu

Shenyu

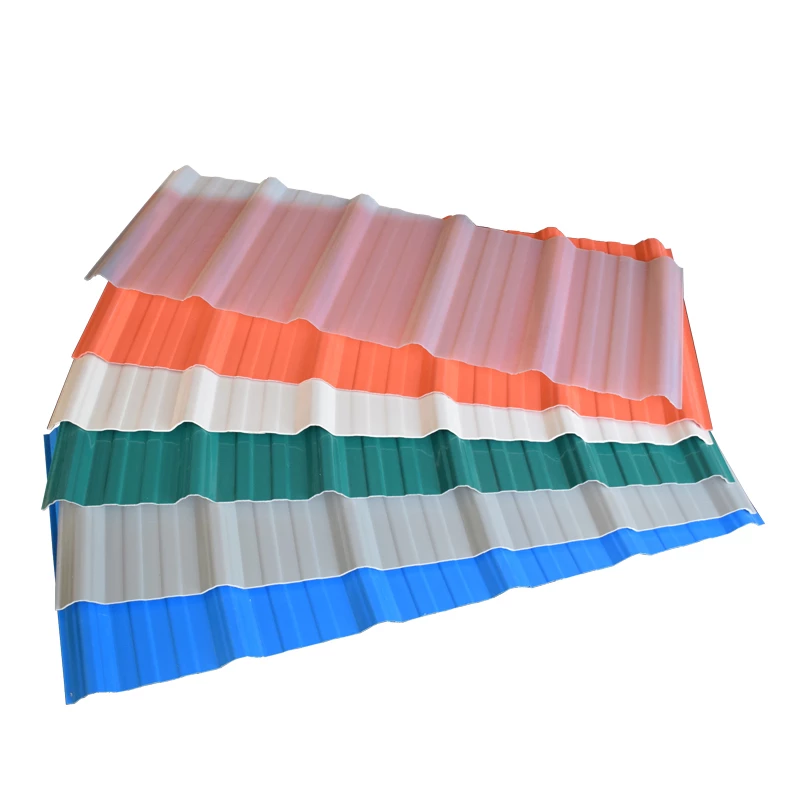

In recent years, ASA PVC roof sheets have gained widespread popularity as a new roofing material in global markets, especially in high-temperature and high-humidity regions. However, many consumers still hold doubts: "Do resin tiles deform under sun exposure? Do they become brittle after just two years? Are they really less durable than color steel tiles?" Is this truly the case? This article delves into the facts behind these misconceptions from a professional perspective, supported by industry data and real-world applications, while providing a practical buying guide.

1. Debunking the Myth: The Thermal Stability of ASA PVC Roof Sheets Has Been Proven in Global High-Temperature Markets

Many believe that synthetic resin tiles cannot withstand heat, but this is a generalization stemming from inferior recycled products. In reality, certified ASA synthetic resin roof tiles offer exceptional high-temperature resistance.

For example, SY/Uniko Resin Roofing Tiles are mainly exported to high-temperature regions along the equator, including:

For example, SY/Uniko Resin Roofing Tiles are mainly exported to high-temperature regions along the equator, including:

- Africa: Kenya, Uganda, with average annual temperatures of 30-35°C;

- Southeast Asia: Thailand, Philippines, Indonesia, where rooftop temperatures can reach 60°C in summer;

- South America: Colombia, Ecuador, with consistently high UV radiation levels year-round.

In these high-temperature, high-UV environments, qualified ASA PVC roof sheets generally withstand heat ranges of 70-80°C, with premium products enduring even higher temperatures and offering a service life exceeding 30 years. This fully demonstrates that properly manufactured ASA resin tiles maintain stable performance even in extreme heat conditions.

2. What Really Causes the "Poor Heat Resistance" Misconception?

The root causes of deformation and brittleness are the use of recycled materials and non-standard production processes—not the material itself.

-Material Differences Determine Heat Resistance Limits:

- Virgin ASA + PVC Materials: Snow-white and translucent, odor-free, with intact molecular structure and heat deformation temperature above 70°C;

- Recycled Materials: Murky color, unpleasant odor, broken molecular chains, significantly reduced heat resistance, softening around 50°C, and becoming powdery or brittle within 2-3 years.

-Three Major Issues Caused by Recycled Materials:

- Severely reduced heat resistance, prone to deformation and sagging;

- Weak UV resistance, leading to rapid fading and aging;

- Environmental and health risks: Potential release of heavy metals and benzene-based harmful substances.

3. What Technical Features Should High-Quality ASA Roof Sheets Have?

Leading brands like SY/Uniko ROOF ensure the high-temperature performance of their ASA PVC roof tiles through the following technological guarantees:

- European Core Formulation: High-weatherability ASA surface layer offers excellent UV and heat aging resistance;

- 100% Virgin Materials: No recycled materials are used, ensuring thermal stability from the source;

- Automated Production Lines: Eliminate defects caused by unstable processes;

- Extreme Environment Testing: Passes cyclic tests from 120°C high temperature to -40°C low temperature with no performance degradation;

- International Certifications: Complies with SGS 3000-hour weather resistance tests and B1 flame retardancy standards.

These technological advancements ensure that SY/Uniko ROOF’s ASA synthetic resin roof tiles are not only heat-resistant but also offer comprehensive advantages such as impact resistance, corrosion resistance, sound insulation, and thermal insulation.

4. Buying Guide: 4 Steps to Identify Heat-Resistant High-Quality ASA Resin Tiles

To avoid purchasing inferior products with poor heat resistance, consumers should evaluate products based on four criteria:

- Check Appearance:

- The cross-section should be fine, uniform, free of particles, and impurities;

- The surface ASA layer should be evenly coated without leaks or patches.

- Test Performance:

- Use a lighter to burn a corner of the tile; virgin materials should not produce black substances or pungent odors;

- If possible, send samples for testing to verify a heat deformation temperature above 70°C.

- Verify Certifications:

- Request authoritative quality inspection reports, material source proof, and international certifications such as SGS and B1 flame retardancy from the manufacturer.

- Choose a Reputable Roof Brand:

- Opt for established brands like SY/Uniko ROOF with years of technical expertise and long-term warranties (e.g., 12 years or more).

5. Conclusion

The notion that "ASA PVC roof sheets are not heat-resistant" is an outdated myth that has been debunked by high-quality products and global market validation. The real factors affecting thermal performance and durability are the use of virgin materials and high-standard craftsmanship and quality control. As a professional uPVC roof sheets manufacturer, SY/Uniko ROOF has served 23 high-temperature and high-humidity regions worldwide, with cumulative applications exceeding 100 million square meters, redefining the performance benchmark for synthetic resin roof tiles.

When making a choice, prioritize standards, brands, and materials—only then can you truly benefit from the long-lasting protection and energy-saving value of ASA resin tiles.

In a nutshell: Heat resistance depends on material quality and technology, not the material’s name.

When making a choice, prioritize standards, brands, and materials—only then can you truly benefit from the long-lasting protection and energy-saving value of ASA resin tiles.

In a nutshell: Heat resistance depends on material quality and technology, not the material’s name.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

How Are Synthetic Resin Roofing Sheet Manufactured? An Inside Look at SY/Uniko ROOF’s Production Process

How Are Synthetic Resin Roofing Sheet Manufactured? An Inside Look at SY/Uniko ROOF’s Production Process