How Are Synthetic Resin Roofing Sheet Manufactured? An Inside Look at SY/Uniko ROOF’s Production Process

Aug 27,2025

Aug 27,2025

Shenyu

Shenyu

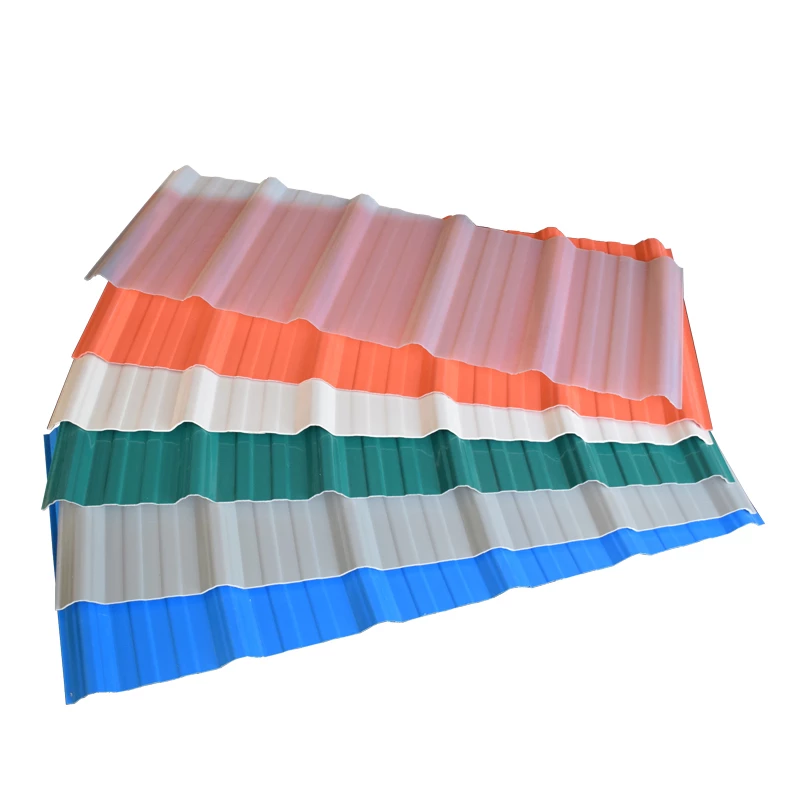

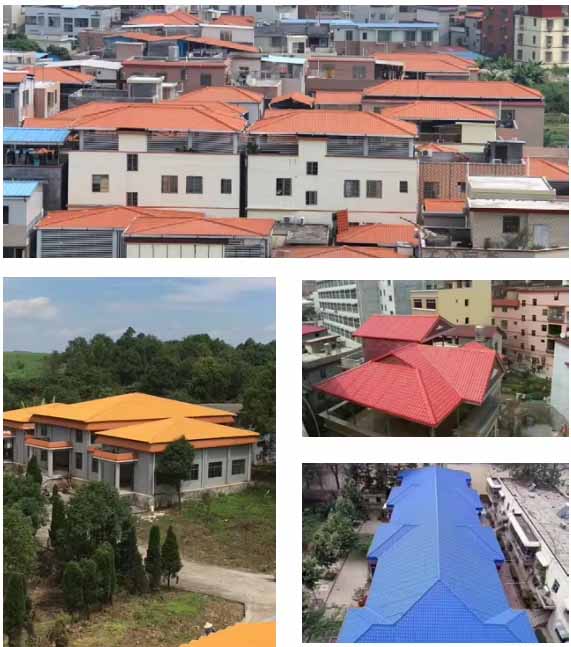

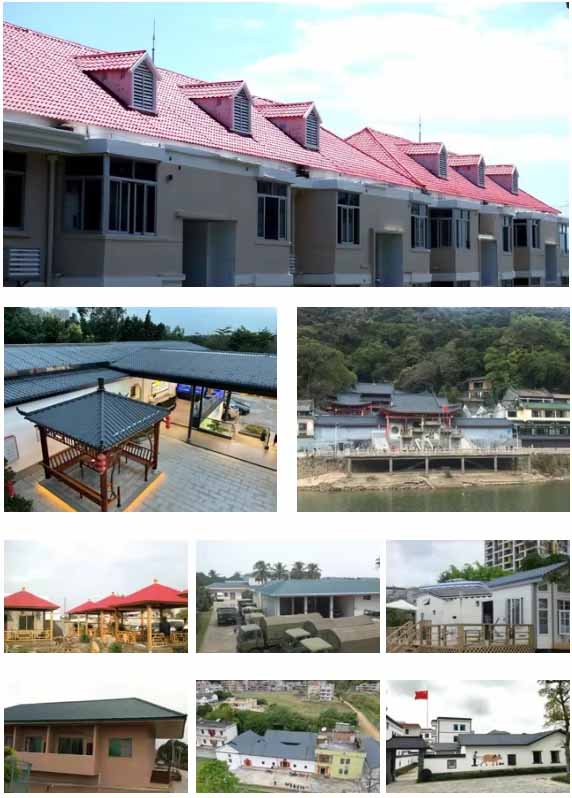

Synthetic resin roofing sheets have emerged as a next-generation, environmentally friendly building material widely promoted for their lightweight properties, high strength, waterproofing, corrosion resistance, flame retardancy, sound insulation, and thermal efficiency. From industrial parks and residential complexes to agricultural markets, commercial spaces, and historical building renovations, ASA UPVC roofing sheets are becoming the material of choice in modern architecture. But how exactly are these high-performance roofing products made? Join us for an exclusive behind-the-scenes tour of SY/Uniko ROOF’s manufacturing process.

Raw Material Selection: The Foundation of Quality

At SY/Uniko ROOF, we believe that exceptional products begin with exceptional materials. The primary components of ASA resin roof tiles are synthetic polymers, specifically PVC (Polyvinyl Chloride) and ASA (Acrylonitrile-Styrene-Acrylate) resins. These materials exhibit plastic flow under mechanical stress while offering superior weather resistance, anti-aging properties, and mechanical strength compared to conventional resins.

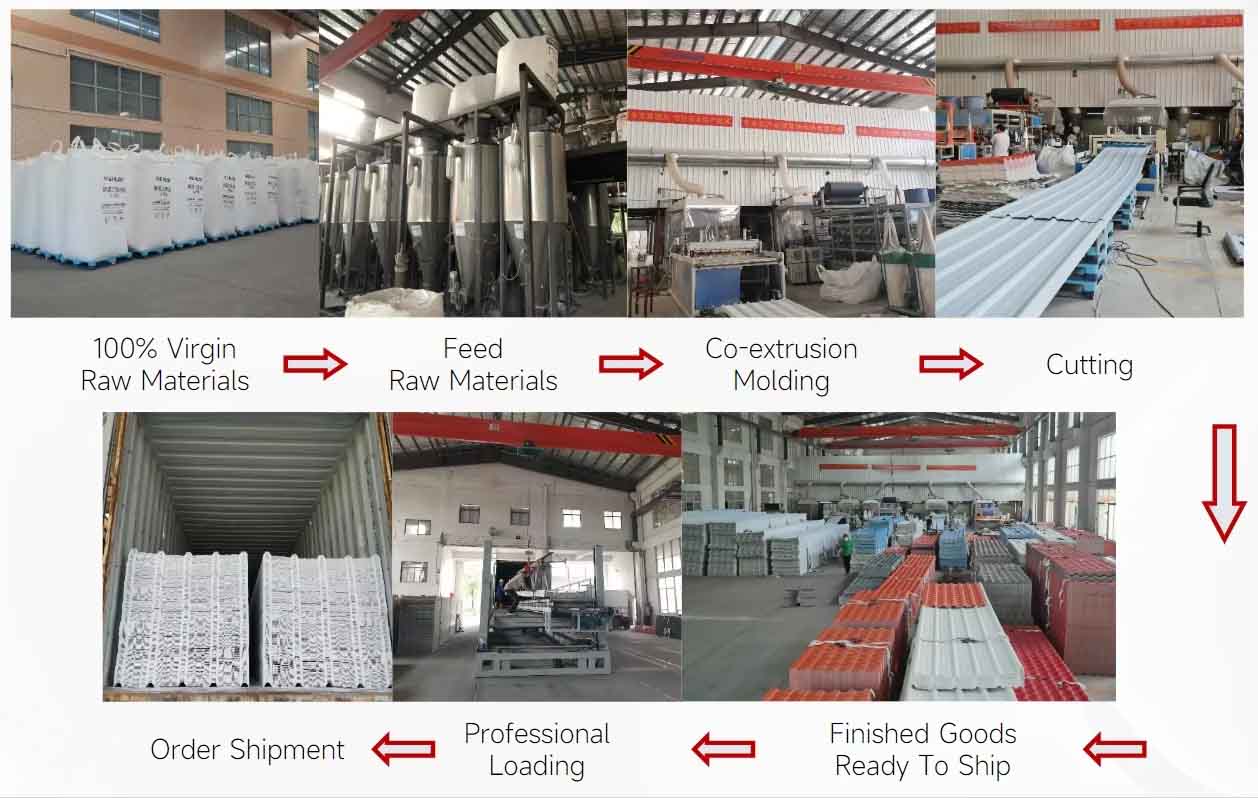

We use only virgin PVC resin to ensure purity and consistency. In addition, a precisely measured blend of additives is incorporated:

We use only virgin PVC resin to ensure purity and consistency. In addition, a precisely measured blend of additives is incorporated:

- Stabilizers to prevent thermal degradation during processing and usage

- Impact modifiers to enhance durability and shock resistance

- Pigments for uniform, long-lasting color

- Lubricants to improve processing fluency

1. Mixing

Accurately weighed raw materials are fed into a high-speed mixer. This step ensures a homogenous blend, setting the stage for the extrusion process.

2. Co-Extrusion

The mixed material is transferred into an extruder, where it is melted under strictly controlled temperatures. This is one of the most critical stages—using advanced co-extrusion technology, the ASA protective layer and PVC substrate are bonded together in a single step.

SY/Uniko ROOF employs a unique four-layer co-extrusion process:

SY/Uniko ROOF employs a unique four-layer co-extrusion process:

- Top Layer: High-weatherability ASA resin for superior UV and weather resistance

- Intermediate Layer: A specially formulated transitional layer ensuring strong interlayer adhesion

- Base Layer: High-strength PVC providing mechanical support and structural stability

- Bottom Layer: Modified PVC optimizing overall performance

3. Molding and Shaping

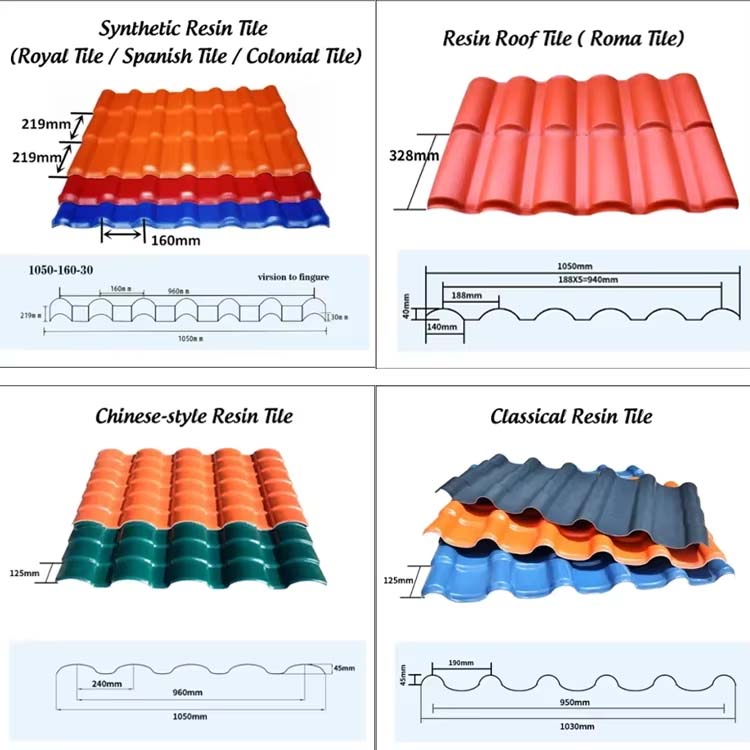

The molten composite material is shaped through precision molds and embossed with the desired tile pattern. SY/Uniko ROOF offers a variety of mold designs to produce different styles of ASA synthetic resin roof tile, meeting diverse architectural aesthetics.

4. Cooling and Cutting

Newly formed tiles pass through a cooling system for solidification and are then automatically cut to standard lengths. Computer-controlled systems ensure dimensional accuracy.

5. Quality Inspection

Every batch undergoes rigorous testing, including:

- Dimensional accuracy checks

- Color consistency evaluation

- Impact resistance tests

- Weathering performance assessments

- Fire resistance verification

Innovation and Technology: The SY/Uniko ROOF Advantage

With 12+ industrial experience and production lines equipped with European technology, SY/Uniko ROOF emphasizes innovation and automation. This not only enhances production efficiency but also guarantees product consistency and reliability.

Our proprietary formulations and process controls ensure that ASA PVC roof tile products offer:

Our proprietary formulations and process controls ensure that ASA PVC roof tile products offer:

- Exceptional weather resistance: Withstands 3000 hours of artificial aging tests, equivalent to 30 years of natural use

- Outstanding temperature resistance: Suitable for environments ranging from -40°C to 120°C

- Excellent mechanical strength: Capable of enduring harsh weather conditions such as strong winds and heavy rain

- Eco-friendly composition: 100% recyclable and compliant with green building standards

Applications: Embracing a New Era of Green Building

As demands for building quality continue to rise, ASA roof sheet products are setting new standards in construction. SY/Uniko ROOF products are certified by SGS, CE, and other international standards, and have been exported to 23 countries and regions, covering over 100 million square meters in applications.

Whether for commercial or residential use, new builds or renovation projects, SY/Uniko ROOF provides comprehensive roofing solutions. We adhere to a "quality first, customer foremost" philosophy and offer a 30-year product warranty, giving our customers confidence and peace of mind.

Whether for commercial or residential use, new builds or renovation projects, SY/Uniko ROOF provides comprehensive roofing solutions. We adhere to a "quality first, customer foremost" philosophy and offer a 30-year product warranty, giving our customers confidence and peace of mind.

Conclusion

Understanding the production process of resin roof tiles reveals the advanced material science, precise engineering, and strict quality control behind every high-quality product. SY/Uniko ROOF is committed to delivering reliable, high-performance roofing solutions through technical expertise and meticulous manufacturing.

When selecting ASA roofing sheet materials, it’s essential to look beyond appearance and price—consider the production technology and quality certifications. SY/Uniko ROOF recommends choosing products that comply with international standards and carry complete quality assurance for long-lasting protection and aesthetic value.

When selecting ASA roofing sheet materials, it’s essential to look beyond appearance and price—consider the production technology and quality certifications. SY/Uniko ROOF recommends choosing products that comply with international standards and carry complete quality assurance for long-lasting protection and aesthetic value.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

Choosing UPVC Roof Tiles for Your Farm: A Guide to Better Animal Housing

Choosing UPVC Roof Tiles for Your Farm: A Guide to Better Animal Housing