UPVC Roof Tile Purchasing Guide: A Comprehensive Solution from Color and Size to Customization

Jan 14,2026

Jan 14,2026

Shenyu

Shenyu

Choosing roofing materials may seem straightforward, but problems often start with overlooked details: confirming colors based solely on digital images, ignoring effective coverage width, lacking physical samples for custom orders, or mismatched accessories. These "minor issues" evolve into color discrepancy disputes, leakage risks, material waste, and project delays once containers arrive on-site and installation begins.

As one of the Best PVC Roofing Manufacturers In Foshan, China, we understand these pain points deeply. Our two brands, SY Roof and Uniko Roof, are dedicated to providing high-quality UPVC roof tiles for global projects. This guide breaks down the critical steps in the purchasing process, helping you identify and mitigate risks early to achieve predictable and successful procurement.

As one of the Best PVC Roofing Manufacturers In Foshan, China, we understand these pain points deeply. Our two brands, SY Roof and Uniko Roof, are dedicated to providing high-quality UPVC roof tiles for global projects. This guide breaks down the critical steps in the purchasing process, helping you identify and mitigate risks early to achieve predictable and successful procurement.

Who Are UPVC Roof Tiles Best Suited For?

Wholesalers and Distributors: Success hinges on focusing on mainstream colors and specifications to maintain inventory turnover. The core risk lies in color variations during replenishment. We mitigate this by maintaining a sealed sample library to ensure color consistency across different batches of PVC roof tiles, protecting you from customer complaints caused by mixed-batch usage.

Trading Companies and Importers: You need more than just high-quality main materials; you require a complete roofing system. We provide perfectly matched accessories such as ridge caps, edge trims, and fasteners, ensuring both aesthetic unity and functional integrity, freeing you from the hassle of "piecing together" incompatible components.

Contractors and Project Owners: On-site labor costs are high. The precise dimensions and predictable overlapping performance of our products significantly improve installation speed and ensure a smooth, even roof surface. The cost savings from efficient installation far outweigh minimal per-unit price advantages.

Trading Companies and Importers: You need more than just high-quality main materials; you require a complete roofing system. We provide perfectly matched accessories such as ridge caps, edge trims, and fasteners, ensuring both aesthetic unity and functional integrity, freeing you from the hassle of "piecing together" incompatible components.

Contractors and Project Owners: On-site labor costs are high. The precise dimensions and predictable overlapping performance of our products significantly improve installation speed and ensure a smooth, even roof surface. The cost savings from efficient installation far outweigh minimal per-unit price advantages.

How to Prevent Color Discrepancy and Fading Complaints?

Never confirm colors based on pictures alone. We recommend a Three-Step Confirmation Process:

- Initial Color Selection: Start with our physical color chart for preliminary screening.

- Physical Sample Confirmation: Review large samples of our UPVC roof sheets under natural light.

- Sealed Reference Sample: Both parties seal and archive the confirmed sample, establishing it as the sole color benchmark for all future production batches.

For regions with high UV exposure, we go beyond standard weather-resistant formulations. Based on specific climatic data, we can recommend material solutions with enhanced resistance to chalking and color change, supported by relevant weathering test reports for your reference.

Key Dimensions Determining Waterproofing, Cost, and Installation Efficiency

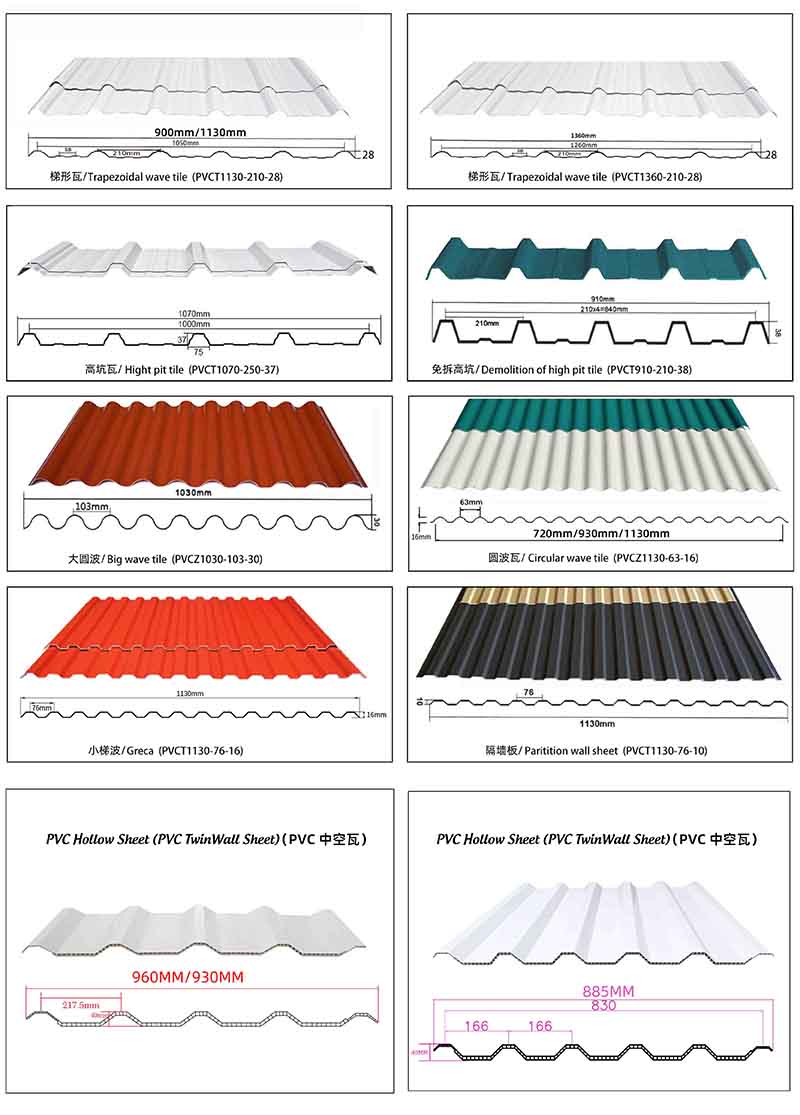

During procurement, it is crucial to distinguish between "total width" and "effective coverage width." The latter deducts the necessary side lap, forming the true basis for calculating material requirements and actual costs. Based on your project's roof pitch, rainfall, and wind load data, we provide scientifically recommended overlapping guidelines.

Sheet length requires balancing aesthetics with practicality: longer sheets reduce seams for a cleaner look but must consider container loading efficiency and on-site handling conditions. As an experienced manufacturer, we help optimize the design, recommending an "optimal length" that balances transportation, handling, and compatibility with common local construction modules.

Sheet length requires balancing aesthetics with practicality: longer sheets reduce seams for a cleaner look but must consider container loading efficiency and on-site handling conditions. As an experienced manufacturer, we help optimize the design, recommending an "optimal length" that balances transportation, handling, and compatibility with common local construction modules.

Customization Options and Understanding MOQ & Lead Times

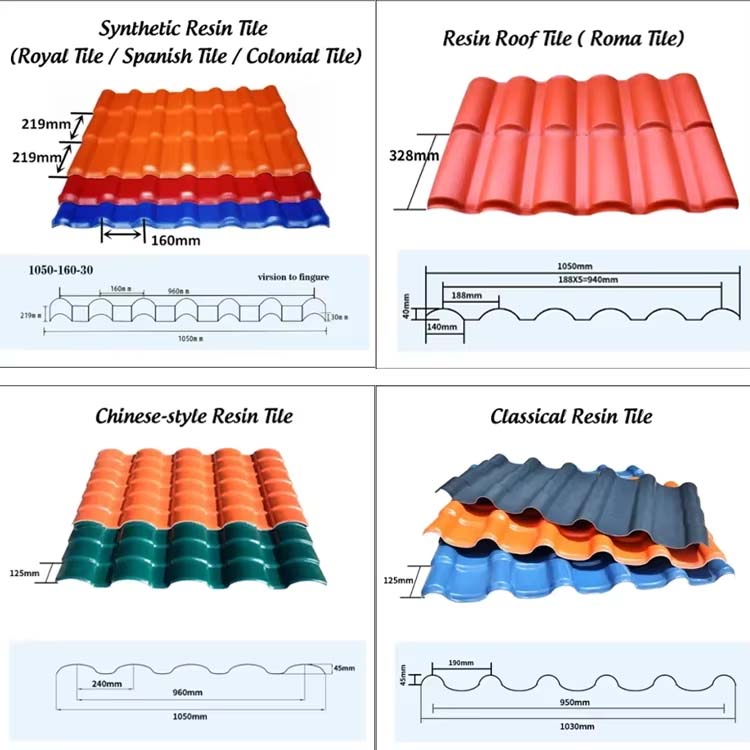

We support in-depth customization to help you build a differentiated product line:

- Color Customization: Matching to Pantone codes or physical samples. This is the primary factor affecting Minimum Order Quantity (MOQ) and lead time.

- Specification Customization: Adjustable length, thickness, and profile.

- Complete System: Provision of matching custom accessories.

- Branding Services: Support for OEM packaging, pallet labels, and carton marking to enhance your brand image and warehouse management efficiency.

A clear customization process ensures smooth cooperation. Please provide a detailed requirements list (color, specs, thickness, accessories, packaging, destination port). We will then produce confirmation samples based on this. We strongly recommend sealing and archiving the final approved sample—it is the most effective tool for guaranteeing color consistency across long-term repeat orders.

What Should a Qualified UPVC Roof Tile Supplier Provide?

Beyond high-quality UPVC roof tile products, a reliable partner should deliver:

- Clear Technical Documentation: Including detailed specification sheets with tolerances and installation guidelines.

- Complete Export Documentation: Commercial invoices, packing lists, compliant shipping marks, and assistance with certifications required for specific markets.

- Quality Consistency Assurance: We not only hold certifications like ISO but, more importantly, define inspection standards and tolerances upfront during production. We provide factory inspection reports and base our quality control for key properties like weather resistance on solid evidence.

- Professional Pre-Sales Support: We proactively inquire about your project's local climate and structural details (pitch, purlin spacing) to recommend appropriate thickness, overlap methods, and fixing solutions, rather than simply selling a product.

Why Choose SY Roof and Uniko Roof?

We serve B2B clients who value stable specifications, consistent appearance, and reliable processes. Our collaboration model is built on a structured confirmation workflow:

- Color: Physical sample confirmation + sealed archive.

- Dimensions: Clear specification of total width, effective coverage width, and overlap, enabling precise calculation.

- Packaging: Robust export-grade packaging with clear SKU labeling designed to minimize shipping damage and warehouse sorting errors.

We understand that successful procurement is not just about competitive pricing but about comprehensive assurance of batch-to-batch consistency, controllable delivery, system compatibility, and traceable accountability. Choosing us means partnering with a reliable PVC Roofing Manufacturer from Foshan, committed to building your long-lasting, worry-free roof—starting from the very first UPVC roof tile.

Pvc Roof Tile Thickness and Size FAQs

Q1: How do you guarantee color consistency across multiple production batches for a single project?

A1: We guarantee it through our Sealed Sample System. For each color, we produce and archive a physical master sample in a controlled environment. Before every production run, we use a professional colorimeter to match the new batch against this master, ensuring a Delta E value of less than 1.0 (virtually indistinguishable to the naked eye). This system, combined with our controlled raw material sourcing, allows us to maintain perfect consistency for projects requiring phased deliveries, eliminating costly mismatches.

Q2: What's the difference between total width and effective coverage width, and how do I calculate the real quantity needed?

A2: This is a critical distinction to avoid costly shortages. Total Width is the physical sheet dimension (e.g., 1080mm). Effective Coverage Width is the width after accounting for side lap (e.g., 1000mm). To calculate real needs: Purchase Quantity = Roof Area / (Effective Width / Total Width). Using our example, for a 1000㎡ roof, you'd need 1080㎡ of material. We provide this data clearly in all quotes and offer a free calculation tool to prevent under-ordering and project delays.

Q3: What is your minimum order quantity (MOQ) for custom colors, and what's the lead time?

A3: Our MOQ is tiered for flexibility. Standard colors from our catalog have a low MOQ. For new custom colors, the standard MOQ is one 20-foot container (approx. 2,000-2,500㎡) to ensure color accuracy and cost-effectiveness. The lead time is typically 30-35 days after color sample confirmation, which includes laboratory matching, your approval of physical samples, and production. We recommend using our standard color palette for smaller projects to save time and cost.

Q4: For high-UV regions like the Middle East, what proof do you provide for weatherability?

A4: Beyond general claims, we provide concrete evidence. Our UPVC tiles for such markets are formulated with enhanced UV stabilizers. We can supply QUV Accelerated Weathering Test Reports (simulating years of sun exposure) showing minimal color shift (∆E) and gloss retention. Additionally, we share technical data sheets with specific UV resistance ratings and, where available, real-world case studies from similar climates.

Q5: What does a "complete roofing system" include, and why is it important?

A5: A complete system is more than just the main sheets. It includes all perfectly matched accessories: ridge caps, hip rolls, eaves closures, and compatible fasteners. Using a mismatched system from different suppliers is the #1 cause of leaks and aesthetic failure. Our system is designed and produced together, ensuring seamless integration, consistent color/aging, and a watertight installation. We provide a single-source solution and comprehensive installation manuals.

Q6: As a wholesaler, how can I prevent complaints about fading or color difference from my end-clients?

A6: Proactive specification is key. We recommend you order and keep a sealed reference sample from us for each color you stock. Use this sample as the binding standard for all future re-orders, not photos or memory. For your clients, educate them on choosing colors suitable for the local climate (lighter colors generally perform better in high heat) and always recommend installing tiles from the same batch on the same visible roof plane. We support you with technical documentation to build your clients' confidence.

A1: We guarantee it through our Sealed Sample System. For each color, we produce and archive a physical master sample in a controlled environment. Before every production run, we use a professional colorimeter to match the new batch against this master, ensuring a Delta E value of less than 1.0 (virtually indistinguishable to the naked eye). This system, combined with our controlled raw material sourcing, allows us to maintain perfect consistency for projects requiring phased deliveries, eliminating costly mismatches.

Q2: What's the difference between total width and effective coverage width, and how do I calculate the real quantity needed?

A2: This is a critical distinction to avoid costly shortages. Total Width is the physical sheet dimension (e.g., 1080mm). Effective Coverage Width is the width after accounting for side lap (e.g., 1000mm). To calculate real needs: Purchase Quantity = Roof Area / (Effective Width / Total Width). Using our example, for a 1000㎡ roof, you'd need 1080㎡ of material. We provide this data clearly in all quotes and offer a free calculation tool to prevent under-ordering and project delays.

Q3: What is your minimum order quantity (MOQ) for custom colors, and what's the lead time?

A3: Our MOQ is tiered for flexibility. Standard colors from our catalog have a low MOQ. For new custom colors, the standard MOQ is one 20-foot container (approx. 2,000-2,500㎡) to ensure color accuracy and cost-effectiveness. The lead time is typically 30-35 days after color sample confirmation, which includes laboratory matching, your approval of physical samples, and production. We recommend using our standard color palette for smaller projects to save time and cost.

Q4: For high-UV regions like the Middle East, what proof do you provide for weatherability?

A4: Beyond general claims, we provide concrete evidence. Our UPVC tiles for such markets are formulated with enhanced UV stabilizers. We can supply QUV Accelerated Weathering Test Reports (simulating years of sun exposure) showing minimal color shift (∆E) and gloss retention. Additionally, we share technical data sheets with specific UV resistance ratings and, where available, real-world case studies from similar climates.

Q5: What does a "complete roofing system" include, and why is it important?

A5: A complete system is more than just the main sheets. It includes all perfectly matched accessories: ridge caps, hip rolls, eaves closures, and compatible fasteners. Using a mismatched system from different suppliers is the #1 cause of leaks and aesthetic failure. Our system is designed and produced together, ensuring seamless integration, consistent color/aging, and a watertight installation. We provide a single-source solution and comprehensive installation manuals.

Q6: As a wholesaler, how can I prevent complaints about fading or color difference from my end-clients?

A6: Proactive specification is key. We recommend you order and keep a sealed reference sample from us for each color you stock. Use this sample as the binding standard for all future re-orders, not photos or memory. For your clients, educate them on choosing colors suitable for the local climate (lighter colors generally perform better in high heat) and always recommend installing tiles from the same batch on the same visible roof plane. We support you with technical documentation to build your clients' confidence.

+86 13924808361

+86 13924808361 sales01@syrooftile.com

sales01@syrooftile.com

Home

Home

A Practical Guide to Choosing the Best UPVC Roofing Tile for Your Agricultural Buildings

A Practical Guide to Choosing the Best UPVC Roofing Tile for Your Agricultural Buildings